Toyota CH-R Service Manual: Inspection

INSPECTION

PROCEDURE

1. INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY (w/o Smart Key System)

HINT:

If the results of the following inspections are as specified but a malfunction has occurred, replace the shift lock control unit assembly.

(a) Inspect the wire harness.

|

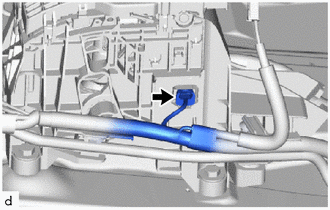

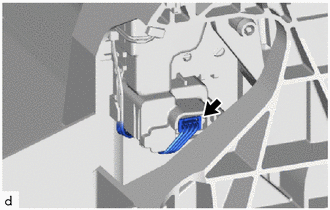

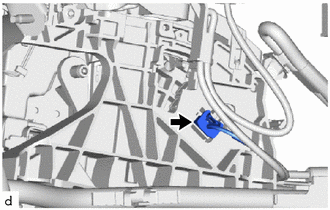

(1) Disconnect the shift lock control ECU connector. |

|

|

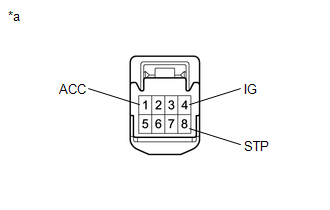

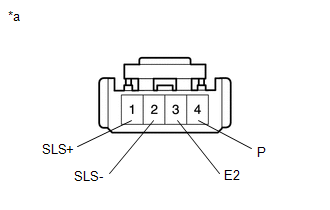

(2) Measure the voltage according to the value(s) in the table below. Standard Voltage:

If the result is not as specified, repair or replace the wire harness or connector. |

|

|

(3) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, repair or replace the wire harness or connector. |

|

(b) Inspect the key interlock solenoid operation signal.

|

(1) Connect the shift lock control ECU connector. |

|

|

(2) Measure the voltage according to the value(s) in the table below. Standard Voltage:

If the result is not as specified, replace the shift lock control unit assembly. HINT: Do not disconnect the shift lock control ECU connector. |

|

(c) Inspect the shift lock solenoid.

|

(1) Disconnect the shift lock solenoid connector. |

|

|

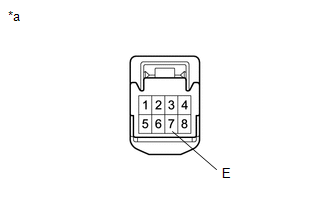

(2) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the shift lock control unit assembly. |

|

2. INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY (w/ Smart Key System)

HINT:

If the results of the following inspections are as specified but a malfunction has occurred, replace the shift lock control unit assembly.

(a) Inspect the wire harness.

|

(1) Disconnect the shift lock control ECU connector. |

|

|

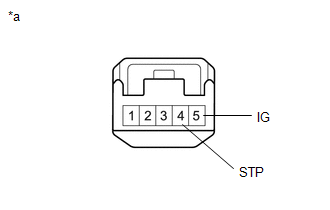

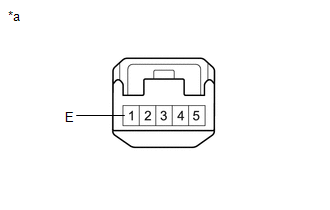

(2) Measure the voltage according to the value(s) in the table below. Standard Voltage:

If the result is not as specified, repair or replace the wire harness or connector. |

|

|

(3) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, repair or replace the wire harness or connector. |

|

(b) Inspect the shift lock solenoid.

|

(1) Disconnect the shift lock solenoid connector. |

|

|

(2) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the shift lock control unit assembly. |

|

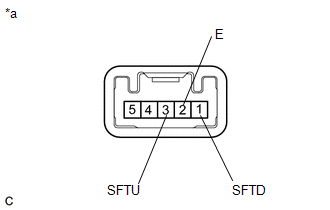

3. INSPECT TRANSMISSION CONTROL SWITCH (SHIFT LOCK CONTROL UNIT ASSEMBLY)

|

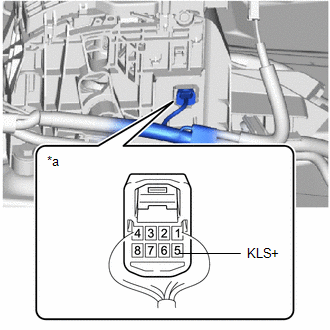

(a) Disconnect the connector from the shift lock control unit assembly. |

|

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the shift lock control unit assembly. |

|

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE SHIFTING HOLE COVER SUB-ASSEMBLY

(a) Disengage the 4 guides and 6 claws to remove the shifting hole cover

sub-assembly from the upper console panel su ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL SHIFT LEVER HOUSING BRACKET SUB-ASSEMBLY

(a) Engage the 4 claws to install the shift lever housing bracket sub-assembly

to the shift lock control unit ...

Other materials:

Toyota CH-R Service Manual > Tire Pressure Warning System: Initialization

INITIALIZATION

NOTICE:

Initialization can be confirmed through the tire pressure warning light.

If the ignition switch off during initialization, the tire pressure

warning ECU and receiver memorizes that initialization was being performed.

Therefore, it is not necessary to p ...

Toyota CH-R Service Manual > Curtain Shield Airbag Assembly: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration)

that must be performed after parts are removed, installed, or replaced during the

curtain shield airbag assembly removal/installation are shown below.

Necessary Procedure After ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0111