Toyota CH-R Service Manual: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during the transmission revolution sensor removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced|

Replacement Part or Procedure |

Necessary Procedure |

Effect/Inoperative when not Performed |

Link |

|---|---|---|---|

|

Disconnect cable from negative battery terminal |

Initialize back door lock |

Power door lock control system |

|

|

Memorize steering angle neutral point |

Lane departure alert system (w/ Steering Control) |

|

|

|

Pre-collision system |

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notice before proceeding with work.

Click here

.gif)

.gif)

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

Click here

.gif)

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

Click here

.gif)

.gif)

.gif)

3. REMOVE BATTERY

Click here

.gif)

4. REMOVE NO. 2 CYLINDER HEAD COVER

Click here

.gif)

5. REMOVE RADIATOR COVER

Click here

.gif)

.gif)

6. REMOVE NO. 1 AIR CLEANER INLET

Click here

.gif)

.gif)

.gif)

7. REMOVE AIR CLEANER CAP WITH AIR CLEANER HOSE

Click here

.gif)

.gif)

8. REMOVE AIR CLEANER CASE SUB-ASSEMBLY

Click here

.gif)

.gif)

9. REMOVE ECM

Click here

.gif)

.gif)

10. REMOVE BATTERY CLAMP SUB-ASSEMBLY

Click here

.gif)

.gif)

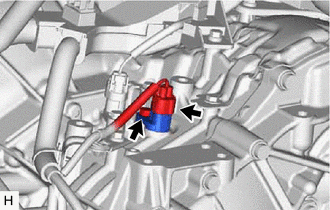

11. REMOVE TRANSMISSION REVOLUTION SENSOR (NIN)

(a) Disconnect the connector.

(b) Remove the bolt and transmission revolution sensor (NIN) from the continuously variable transaxle assembly.

(c) Remove the O-ring from the transmission revolution sensor (NIN).

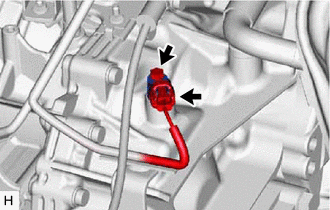

12. REMOVE TRANSMISSION REVOLUTION SENSOR (NOUT)

(a) Disconnect the connector.

(b) Remove the bolt and transmission revolution sensor (NOUT) from the continuously variable transaxle assembly.

(c) Remove the O-ring from the transmission revolution sensor (NOUT).

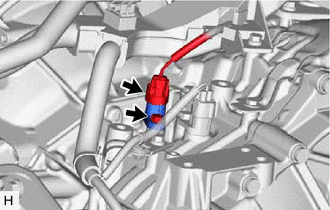

13. REMOVE TRANSMISSION REVOLUTION SENSOR (NT)

(a) Disconnect the connector.

(b) Remove the bolt and transmission revolution sensor (NT) from the continuously variable transaxle assembly.

(c) Remove the O-ring from the transmission revolution sensor (NT).

Components

Components

COMPONENTS

ILLUSTRATION

*1

AIR CLEANER CAP WITH AIR CLEANER HOSE

*2

AIR CLEANER CASE SUB-ASSEMBLY

*3

BATTERY CLAMP SUB-ASSEM ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT TRANSMISSION REVOLUTION SENSOR (NIN)

*a

Component without harness connected

(Transmission Revolution Sensor (NIN))

(a) Measure t ...

Other materials:

Toyota CH-R Service Manual > Front Door Window Frame Moulding: Components

COMPONENTS

ILLUSTRATION

*A

for TMMT Made

*B

for TMC Made

*1

DOOR FRAME UPPER GARNISH

*2

FRONT DOOR FIX WINDOW GLASS

*3

FRONT DOOR FRONT LOWER FRAME SUB-ASSEMBLY

*4 ...

Toyota CH-R Service Manual > Washer Motor: Inspection

INSPECTION

PROCEDURE

1. INSPECT WINDSHIELD WASHER MOTOR AND PUMP ASSEMBLY (for Front Side)

HINT:

This check should be performed with the windshield washer motor and pump assembly

installed to the windshield washer jar assembly.

(a) Fill the windshield washer jar assembly with washer fluid.

...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0069