Toyota CH-R Service Manual: Input / Turbine Speed Sensor "A" Circuit No Signal (P0717,P07BF,P07C0)

DESCRIPTION

The ECM receives a signal from the transmission revolution sensor (NT) installed in the continuously variable transaxle to control the lock-up engagement pressure and forward and reverse clutch pressure.

The transmission revolution sensor (NT) detects the continuously variable transaxle input shaft speed and sends a signal to the ECM.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Memory |

|---|---|---|---|---|---|

|

P0717 |

Input / Turbine Speed Sensor "A" Circuit No Signal |

All of the following conditions are met (1 trip detection logic):

|

|

Comes on |

DTC stored |

|

P07BF |

Input/Turbine Speed Sensor "A" Circuit Low |

There is no malfunction in transmission revolution sensor (NT) signals, and the transmission revolution sensor (NT) output voltage is less than 0.2 V for 2 seconds (1 trip detection logic). |

|

Comes on |

DTC stored |

|

P07C0 |

Input/Turbine Speed Sensor "A" Circuit High |

There is no malfunction in transmission revolution sensor (NT) signals, and the transmission revolution sensor (NT) output voltage is higher than 1.8 V for 2 seconds (1 trip detection logic). |

|

Comes on |

DTC stored |

MONITOR DESCRIPTION

The transmission revolution sensor (NT) detects the transaxle input shaft speed. The ECM determines the necessary gear ratio based on a comparison of the transmission revolution sensor (NT) (input shaft speed) with the transmission revolution sensor (NOUT) (output shaft speed).

When the output shaft speed is higher than the expected value and the input shaft speed is less than 300 rpm while driving with the shift lever in D, the ECM will determine that the transmission revolution sensor (NT) is malfunctioning. The ECM will illuminate the MIL and store a DTC.

MONITOR STRATEGY

|

Related DTCs |

P0717: Input speed sensor (NT) / Verify pulse input P07BF: Input speed sensor (NT) / Range check (Low voltage) P07C0: Input speed sensor (NT) / Range check (High voltage) |

|

Required sensors/Components |

Transmission revolution sensor (NT) |

|

Frequency of operation |

Continuous |

|

Duration Conditions |

2 seconds |

|

MIL operation |

Immediately |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

All|

Battery voltage |

8 V or more |

|

Time after Battery voltage 8 V or more |

0.5 seconds or more |

|

Write Inhibit |

permit |

|

Time after Write status forbiddance to permit |

0.5 seconds or more |

|

Ignition switch |

ON |

|

Time after Ignition switch OFF to ON |

0.5 seconds or more |

|

Starter |

OFF |

|

Time after Starter ON to OFF |

0.5 seconds or more |

|

Park Neutral Position switch |

OFF |

|

All of the following conditions are met: |

- |

|

Output shaft revolution |

300 rpm or more |

|

Transmission "R" range switch |

OFF |

|

Transmission Range Switch circuit fail (P0705) (Pending + MIL) |

Not detected |

|

Engine |

Running |

|

Turbine Speed Sensor Range check fail (P07BF, P07C0) (Pending / MIL) |

Not detected |

|

Output Speed Sensor revolution |

1100 rpm or more |

|

One of the following conditions is met: |

- |

|

Command to Shift Solenoid |

OFF |

|

Command to Torque Converter Clutch Solenoid |

ON |

|

Shift Solenoid circuit fail (P099B, P099C) (Pending + MIL) |

Not detected |

|

Torque Converter Clutch Solenoid circuit fail (P2769, P2770) (Pending + MIL) |

Not detected |

|

Pressure Control Solenoid circuit fail (P2822, P282B) (Pending + MIL) |

Not detected |

|

Turbine Speed Sensor pulse input fail (P0717) (Pending / MIL) |

Not detected |

TYPICAL MALFUNCTION THRESHOLDS

P0717:|

Turbine speed (Input speed) sensor revolution |

Less than 300 rpm |

|

Turbine speed (Input speed) sensor output voltage |

Less than 0.2 V |

|

Turbine speed (Input speed) sensor output voltage |

Higher than 1.8 V |

COMPONENT OPERATING RANGE

P0717:|

Turbine speed (Input speed) sensor revolution |

300 rpm or more |

|

Turbine speed (Input speed) sensor output voltage |

0.2 to 1.8 V |

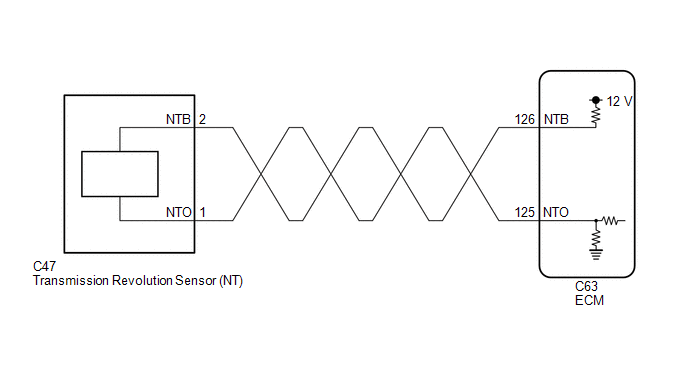

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Perform initialization when parts related to the continuously variable

transaxle are replaced.

Click here

.gif)

- Check that no DTCs are stored after performing initialization.

Click here

.gif)

- Perform the universal trip to clear permanent DTCs.

Click here

.gif)

HINT:

After performing repair, clear the DTCs and perform the following procedure to check that DTCs are not output.

- Drive the vehicle for 2 seconds or more at 6 km/h (4 mph) or more with the shift lever in D.

- Check for DTCs again.

Click here

.gif)

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (SPD (NT) AND NT SENSOR VOLTAGE) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Data List.

Powertrain > Engine and ECT > Data List|

Tester Display |

|---|

|

SPD (NT) |

|

NT Sensor Voltage |

(e) In accordance with the display on the Techstream, read the Data List.

Powertrain > Engine and ECT > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

SPD (NT) |

Input turbine speed |

Min.: 0 rpm Max.: 12750 rpm |

|

Data is displayed in increments of 50 rpm. |

|

NT Sensor Voltage |

Input turbine speed (NT) sensor output voltage |

Min.: 0.000 V Max.: 4.999 V |

0.2 to 1.8 V: Engine idling (Vehicle stopped with shift lever in P or N) |

- |

|

Result |

Proceed to |

|---|---|

|

Data display is not within Normal Condition range |

A |

|

Data display is within Normal Condition range |

B |

| B | .gif) |

GO TO STEP 5 |

|

|

2. |

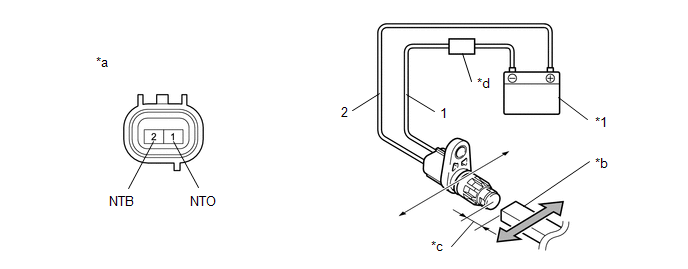

INSPECT TRANSMISSION REVOLUTION SENSOR (NT) |

(a) Remove the transmission revolution sensor (NT).

Click here

.gif)

(b) Connect the battery to the sensor as shown in the illustration.

|

*1 |

Battery |

- |

- |

|

*a |

Component without harness connected (Transmission Revolution Sensor (NT)) |

*b |

Magnet |

|

*c |

5 mm or less |

*d |

Ammeter |

(c) Wave a magnetic object left and right in front of the transmission revolution sensor (NT) tip (5 mm (0.197 in.) or less) to change the high/low signals while measuring the current.

NOTICE:

Make sure to wave the magnetic object during the inspection. The current will not change without waving the magnetic object as indicated by the arrow in the illustration.

(d) Measure the current according to the value(s) in the table below.

Standard Current:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (NTO) - 2 (NTB) |

Low signal |

4 to 8 mA |

|

1 (NTO) - 2 (NTB) |

High signal |

12 to 16 mA |

| NG | .gif) |

REPLACE TRANSMISSION REVOLUTION SENSOR (NT) |

|

|

3. |

CHECK HARNESS AND CONNECTOR (TRANSMISSION REVOLUTION SENSOR (NT) - ECM) |

(a) Disconnect the C47 transmission revolution sensor (NT) connector.

(b) Disconnect the C63 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C47-1 (NTO) - C63-125 (NTO) |

Always |

Below 1 Ω |

|

C47-2 (NTB) - C63-126 (NTB) |

Always |

Below 1 Ω |

|

C47-1 (NTO) or C63-125 (NTO) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C47-2 (NTB) or C63-126 (NTB) - Body ground and other terminals |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (TRANSMISSION REVOLUTION SENSOR (NT) - ECM) |

|

|

4. |

REPLACE ECM |

(a) Replace the ECM.

Click here

.gif)

| NEXT | .gif) |

PERFORM INITIALIZATION |

|

5. |

REPLACE ECM |

(a) Replace the ECM.

Click here

.gif)

| NEXT | .gif) |

PERFORM INITIALIZATION |

Brake ECU Malfunction (P1750)

Brake ECU Malfunction (P1750)

DESCRIPTION

HINT:

This DTC P1750 is applicable to Mexico models only.

When the ECM receives a malfunction signal from the skid control ECU (brake actuator

assembly), DTC P1750 is stored.

...

Transmission Fluid Temperature Sensor "A" Circuit Low Input (P0712,P0713)

Transmission Fluid Temperature Sensor "A" Circuit Low Input (P0712,P0713)

DESCRIPTION

The CVT fluid temperature sensor converts the fluid temperature into a resistance

value which is detected by the ECM.

The sensor resistance changes with the CVT fluid temperature. As t ...

Other materials:

Toyota CH-R Service Manual > Navigation System: Freeze Frame Data

FREEZE FRAME DATA

CHECK FREEZE FRAME DATA

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Navigation System / Trouble

Codes.

Body Electrical > Navigation System > Trouble Codes

(e) ...

Toyota CH-R Service Manual > Immobiliser System(w/o Smart Key System): Unmatched Key Code (B2795)

DESCRIPTION

This DTC is stored when a key with a different vehicle serial number is inserted

into the ignition key cylinder.

DTC No.

Detection Item

DTC Detection Condition

Trouble Area

Note

B2795

Unmatched Key Cod ...

Toyota C-HR (AX20) 2023-2025 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0125

.gif)