Toyota CH-R Service Manual: Installation

INSTALLATION

CAUTION / NOTICE / HINT

PROCEDURE

1. INSTALL BRAKE ACTUATOR BRACKET CUSHION

(a) Install the brake actuator bracket cushion to the brake actuator bracket assembly.

2. INSTALL NO. 1 BRAKE ACTUATOR CASE COLLAR

(a) Install the No. 1 brake actuator case collar to the brake actuator bracket cushion.

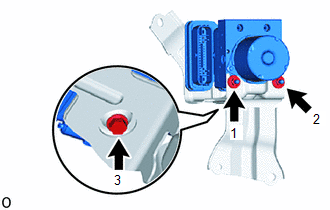

3. INSTALL BRAKE ACTUATOR ASSEMBLY

(a) Temporarily install the brake actuator assembly with the 2 nuts and bolt.

|

(b) Fully tighten the 2 nuts and bolt in the order shown in the illustration. Torque: 6.5 N·m {66 kgf·cm, 58 in·lbf} NOTICE:

|

|

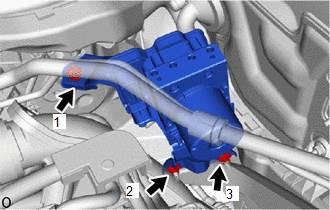

4. INSTALL BRAKE ACTUATOR WITH BRACKET

(a) Temporarily install the brake actuator with bracket to the vehicle body with the bolt and 2 nuts.

|

(b) Fully tighten the bolt and 2 nuts in the order shown in the illustration. Torque: 19 N·m {194 kgf·cm, 14 ft·lbf} NOTICE: Do not damage the brake tubes. |

|

|

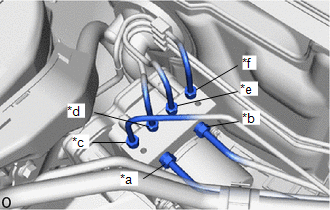

(c) Temporarily tighten each brake line to the correct position on the brake actuator assembly as shown in the illustration. |

|

|

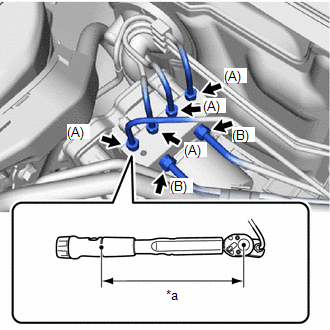

(d) Using a 10 mm and 12 mm union nut wrench, connect the 6 brake tubes to the brake actuator assembly. Torque: Specified tightening torque (A) : 15.2 N·m {155 kgf·cm, 11 ft·lbf} Specified tightening torque (B) : 19.5 N·m {199 kgf·cm, 14 ft·lbf} NOTICE:

HINT:

|

|

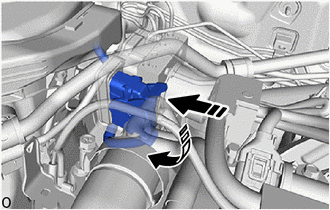

(e) Connect the connector to the brake actuator assembly and lock the lock lever.

NOTICE:

- Make sure that the actuator connector can be connected smoothly. Do not allow water, oil or dirt to enter the connector.

- Make sure that the connector is locked securely.

.png) |

Connect the connector |

.png) |

Lock the lock lever |

5. INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

Click here

.gif)

.gif)

6. INSTALL BATTERY

Click here

.gif)

7. INSTALL COWL BODY MOUNTING REINFORCEMENT RH

Click here

.gif)

.gif)

8. INSTALL COWL BODY MOUNTING REINFORCEMENT LH

Click here

.gif)

.gif)

9. INSTALL WATER GUARD PLATE LH

Click here

.gif)

.gif)

10. INSTALL NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

Click here

.gif)

.gif)

11. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

Click here

.gif)

.gif)

12. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Click here

.gif)

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

Click here

.gif)

.gif)

.gif)

13. BLEED BRAKE SYSTEM

Click here

.gif)

.gif)

14. INSPECT BRAKE ACTUATOR USING TECHSTREAM

Click here

.gif)

15. PERFORM SYSTEM VARIANT LEARNING

Click here

.gif)

.gif)

16. CHECK FOR AND CLEAR DTCS

Click here

.gif)

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

PROCEDURE

1. CONNECT TECHSTREAM

(a) Connect the Techstream to the DLC3 with the ignition switch off.

(b) Start the engine and run it at idle.

(c) Tu ...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration)

that must be performed after parts are removed, installed, or replaced during th ...

Other materials:

Toyota CH-R Service Manual > Meter / Gauge System: System Description

SYSTEM DESCRIPTION

INPUT AND OUTPUT SIGNALS OF COMBINATION METER ASSEMBLY

(a) Meter or Gauge

Item

Condition

Input/Output

Communication line

Signal

Component

Speedometer

Gauge

Input

...

Toyota CH-R Service Manual > Exterior Panels / Trim: Wheel Opening Moulding(for Front)

Components

COMPONENTS

ILLUSTRATION

*1

FRONT FENDER MOULDING SUB-ASSEMBLY

-

-

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH and LH sides.

The procedure listed below is for the LH side.

...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0067