Toyota CH-R Service Manual: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during the seat position airbag sensor removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced|

Replacement Part or Procedure |

Necessary Procedures |

Effects/Inoperative when not performed |

Link |

|---|---|---|---|

|

Disconnect cable from negative battery terminal |

Memorize steering angle neutral point |

Lane departure alert system (w/ Steering Control) |

|

|

Pre-collision system |

|||

|

Initialize back door lock |

Power door lock control system |

|

PROCEDURE

1. REMOVE FRONT SEAT ASSEMBLY

Click here .gif)

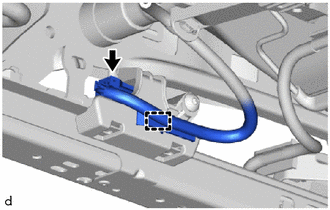

2. REMOVE SEAT SLIDE POSITION SENSOR PROTECTOR

|

(a) Disengage the clamp and disconnect the connector. |

|

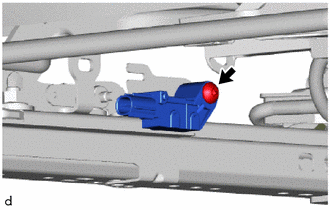

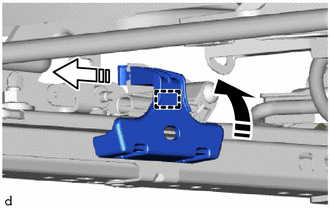

(b) Pull the seat slide position sensor protector in the direction indicated by the arrow (1), to disengage the pin, and then slide the seat slide position sensor protector in the direction indicated by the arrows (2) shown in the illustration to remove it.

.png) |

Remove in this Direction (1) |

.png) |

Remove in this Direction (2) |

3. REMOVE SEAT POSITION AIRBAG SENSOR

|

(a) Using a T30 "TORX" socket wrench, remove the bolt and seat position airbag sensor. |

|

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

CAUTION:

Be sure to correctly follow the removal and installation procedures for the seat

position airbag sensor.

PROCEDURE

1. INSPECT SEAT POSITIO ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL SEAT POSITION AIRBAG SENSOR

(a) Insert the pin into the installation hole and temporarily install

the seat position airbag sensor to the seat rail b ...

Other materials:

Toyota CH-R Service Manual > Immobiliser System(w/ Smart Key System): Registration

REGISTRATION

PROCEDURE

1. CAUTION REGARDING INTERFERENCE WITH ELECTRONIC DEVICES

CAUTION:

People with implantable cardiac pacemakers, cardiac resynchronization

therapy-pacemakers or implantable cardioverter defibrillators should keep

away from the smart key system antennas. The r ...

Toyota CH-R Service Manual > Automatic High Beam System: Precaution

PRECAUTION

IGNITION SWITCH EXPRESSIONS

(a) The type of ignition switch used on this model differs depending on the specifications

of the vehicle. The expressions listed in the table below are used in this section.

Expression

Ignition Switch (Position)

Engine Swi ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0083