Toyota CH-R Service Manual: Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

NOTICE:

- Do not drop the power steering ECU assembly, strike it with tools or subject it to impacts.

- If the power steering ECU assembly is subjected to an impact, replace it with a new one.

- Do not pull the wire harness.

- Do not allow any moisture to come into contact with the power steering ECU assembly.

- Do not loosen any bolts not mentioned in the procedure.

- Do not allow any foreign matter to contaminate the power steering ECU assembly.

PROCEDURE

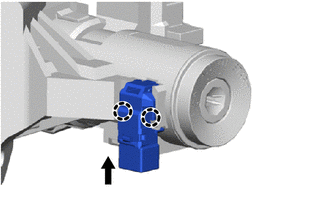

1. INSTALL ELECTRIC POWER STEERING MOTOR SHAFT DAMPER

Click here

.gif)

2. INSTALL POWER STEERING ECU ASSEMBLY

Click here

.gif)

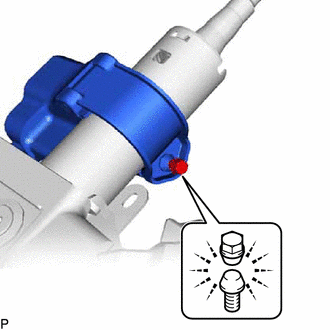

3. INSTALL STEERING LOCK ACTUATOR ASSEMBLY (w/ Smart Key System)

HINT:

When replacing the steering lock actuator assembly, refer to Registration.

Click here

.gif)

|

(a) Install the steering lock actuator assembly with the tapered-head bolt. |

|

(b) Tighten the tapered-head bolt until the bolt head breaks off.

4. INSTALL KEY INTERLOCK SOLENOID (w/o Smart Key System)

|

(a) Install the key interlock solenoid to the upper steering column bracket assembly with the screw. |

|

5. INSTALL IGNITION OR STARTER SWITCH ASSEMBLY (w/o Smart Key System)

|

(a) Install the ignition or starter switch assembly with the 2 screws. |

|

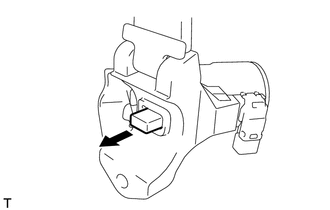

6. INSTALL UN-LOCK WARNING SWITCH ASSEMBLY (w/o Smart Key System)

|

(a) Engage the 2 claws to install the un-lock warning switch assembly to the upper steering column bracket assembly. |

|

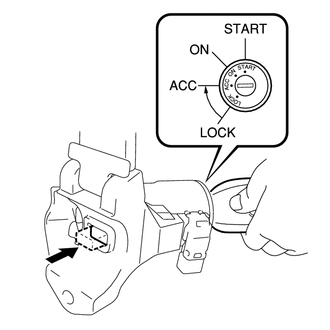

7. INSTALL IGNITION SWITCH LOCK CYLINDER ASSEMBLY (w/o Smart Key System)

(a) Make sure that the ignition switch lock cylinder assembly is in the ACC position.

(b) Install the ignition switch lock cylinder assembly.

8. INSPECT STEERING LOCK OPERATION (w/o Smart Key System)

|

(a) Check that the steering lock mechanism is activated when the key is removed. |

|

|

(b) Check that the steering lock mechanism is deactivated when the key is inserted and turned to the ACC position. If there is any abnormality, replace the ignition switch lock cylinder assembly. |

|

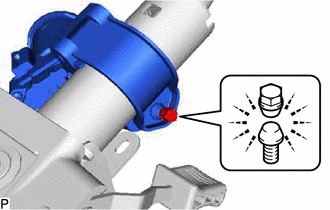

9. INSTALL UPPER STEERING COLUMN BRACKET WITH SWITCH ASSEMBLY (w/o Smart Key System)

|

(a) Install the upper steering column bracket with switch assembly with the tapered-head bolt. |

|

(b) Tighten the tapered-head bolt until the bolt head breaks off.

10. INSTALL TRANSPONDER KEY COIL (w/o Smart Key System)

Click here

.gif)

Installation

Installation

INSTALLATION

PROCEDURE

1. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

2. INSTALL STEERING COLUMN ASSEMBLY

NOTICE:

Make sure that the wire harness is not interfering with the steering column assembly ...

Other materials:

Toyota CH-R Service Manual > Continuously Variable Transaxle System: Transmission Fluid Pressure Sensor/Switch "A" Circuit Low (P0842,P0843)

DESCRIPTION

The ECM performs learning control for the belt clamping pressure based on the

belt clamping pressure signal, which is output by the oil pressure sensor.

DTC No.

Detection Item

DTC Detection Condition

Trouble Area

MIL

M ...

Toyota CH-R Service Manual > Air Conditioning System(for Automatic Air Conditioning System With Side-mounted

Air Conditioner Pressure Sensor): Data List / Active Test

DATA LIST / ACTIVE TEST

DATA LIST

NOTICE:

In the table below, the values listed under "Normal Condition" are reference

values. Do not depend solely on these reference values when deciding whether a part

is faulty or not.

HINT:

Using the Techstream to read the Data List allows the ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0071

.png)

.png)