Toyota CH-R Service Manual: Installation

INSTALLATION

PROCEDURE

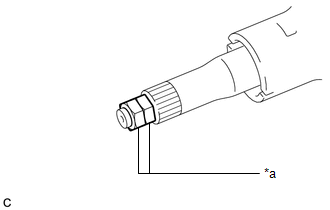

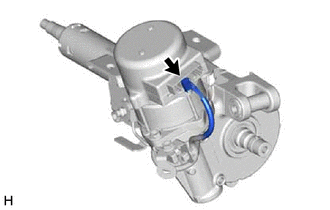

1. INSTALL ELECTRIC POWER STEERING MOTOR SHAFT DAMPER

.png) |

Grease |

(a) Apply grease to a new electric power steering motor shaft damper.

NOTICE:

First wipe off the existing grease from the serrated part, and then apply the dedicated grease supplied with a new power steering ECU assembly or electric power steering column sub-assembly.

(b) Install the electric power steering motor shaft damper to the electric power steering column sub-assembly.

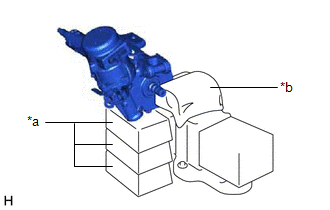

2. INSTALL POWER STEERING ECU ASSEMBLY

NOTICE:

- Do not drop the power steering ECU assembly, strike it with tools or subject it to impacts.

- If the power steering ECU assembly is subjected to an impact, replace it with a new one.

- Do not pull the wire harness of the electric power steering column sub-assembly.

- Do not allow any moisture to come into contact with the power steering ECU assembly.

- Do not loosen any bolts not mentioned in the procedure.

- Do not allow any foreign matter to contaminate the power steering ECU assembly.

(a) for Type A:

(1) Using a T40 "TORX" socket wrench, temporarily install the power steering ECU assembly to the electric power steering column subassembly with the 2 screws.

NOTICE:

When temporarily installing the 2 screws to the power steering ECU assembly, do not tighten them all the way down.

(b) for Type B:

(1) Temporarily install the power steering ECU assembly to the electric power steering column sub-assembly with the 2 bolts.

NOTICE:

When temporarily installing the 2 bolts to the power steering ECU assembly, do not tighten them all the way down.

|

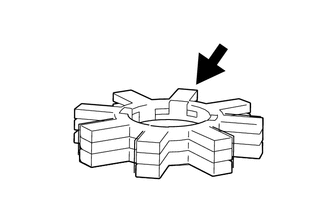

(c) Install 2 service nuts to the steering main shaft. Recommended Service Nut: Thread Diameter 12.0 mm (0.472 in.) Thread Pitch 1.25 mm (0.0492 in.) |

|

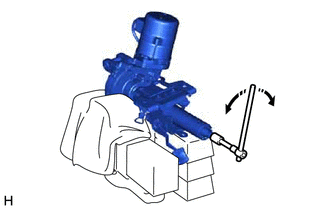

(d) Simultaneously rotate the service nut that was installed first counterclockwise and rotate the service nut that was installed second clockwise to lock them.

NOTICE:

Do not apply excessive torque to the service nuts by using a tool such as an impact wrench.

HINT:

The service nuts are used for turning the steering main shaft during inspection of the steering main shaft rotating torque.

Remove the service nuts after performing this inspection.

|

(e) Secure the steering column assembly in a vise using aluminum plates, cloths and wooden blocks. NOTICE:

|

|

|

(f) Rotate the steering main shaft 180 degrees counterclockwise and then 180 degrees clockwise at a speed of 60 rpm, and repeat 2 to 3 times to center the axis of the power steering ECU assembly. [*1] |

|

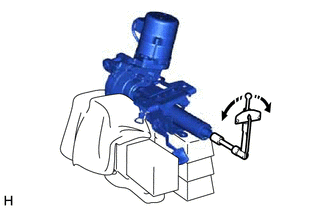

(g) for Type A:

(1) Using a T40 "TORX" socket wrench, tighten the 2 screws. [*2]

Torque:

18.5 N·m {189 kgf·cm, 14 ft·lbf}

(h) for Type B:

(1) Tighten the 2 bolts. [*2]

Torque:

18.5 N·m {189 kgf·cm, 14 ft·lbf}

|

(i) Using a torque wrench, measure the turning torque of the steering main shaft. Preload: 1.2 to 2.4 N*m (13 to 24 kgf*cm, 11 to 21 in.*lbf) NOTICE: Ensure that there is no abnormal resistance during rotation. If the turning torque is not as specified, loosen the 2 bolts and repeat steps [*1] and [*2] to recenter the axis of the power steering ECU assembly. |

|

(j) Remove the 2 service nuts.

|

(k) Connect the connector. |

|

3. INSTALL STEERING COLUMN ASSEMBLY

Click here

.gif)

4. TORQUE SENSOR ZERO POINT CALIBRATION

Click here

.gif)

5. ASSIST MAP WRITING

Click here

.gif)

Components

Components

COMPONENTS

ILLUSTRATION

*1

ELECTRIC POWER STEERING MOTOR SHAFT DAMPER

*2

POWER STEERING ECU ASSEMBLY

*3

ELECTRIC POWER STEER ...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration)

that must be performed after parts are removed, installed, or replaced during th ...

Other materials:

Toyota CH-R Service Manual > Maintenance: Front Turn Signal Light Bulb

Components

COMPONENTS

ILLUSTRATION

*1

FRONT TURN SIGNAL LIGHT BULB

*2

FRONT TURN SIGNAL LIGHT SOCKET AND WIRE SUB-ASSEMBLY

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH and LH sides.

The ...

Toyota CH-R Service Manual > Audio And Visual System(for Radio And Display Type): Noise Occurs or Sound Skips when Portable Player Plays

CAUTION / NOTICE / HINT

HINT:

Perform this check with the portable player volume set at an appropriate

level.

Make sure that there are no obstructions between the portable player

and radio and display receiver assembly that may block signals, and that

the portable player an ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0084