Toyota CH-R Service Manual: Installation

INSTALLATION

PROCEDURE

1. INSTALL BRAKE BOOSTER GASKET

(a) Install a new brake booster gasket to the brake booster assembly.

2. INSTALL BRAKE BOOSTER ASSEMBLY

(a) Temporarily install the brake booster assembly to the vehicle body.

NOTICE:

Do not apply excessive force to the brake lines or refrigerant lines.

(b) Temporarily install the clevis lock nut and brake master cylinder push rod clevis to the brake booster assembly.

NOTICE:

Fully tighten the clevis lock nut when adjusting the brake pedal height.

|

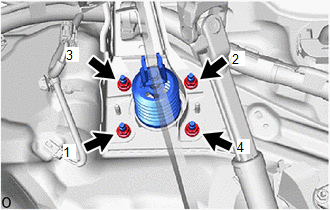

(c) Install the 4 nuts to secure the brake booster assembly. Torque: 12.7 N·m {130 kgf·cm, 9 ft·lbf} NOTICE: Tighten the 4 nuts in the order shown in the illustration. |

|

(d) Remove the protective tape.

(e) Engage the 2 clamps to install the fuel pipe to the fuel pipe clamp.

(f) Engage the 4 clamps to install the brake tube to the 2 brake tube clamps.

(g) Connect the vacuum warning switch connector.

3. CONNECT CHECK VALVE TO CONNECTOR TUBE HOSE

(a) Connect the check valve to connector tube hose to the brake booster assembly and slide the clip to secure it.

4. INSTALL DASH PANEL HEAT INSULATOR

|

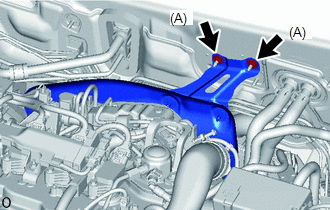

(a) Temporarily install dash panel heat insulator to the vehicle body with the 2 nuts (A). |

|

|

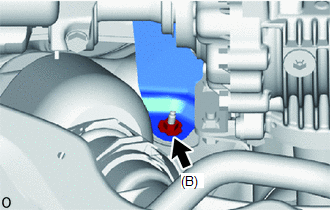

(b) Install the nut (B). Torque: 5.0 N·m {51 kgf·cm, 44 in·lbf} |

|

(c) Tighten the 2 nuts (A).

Torque:

5.0 N·m {51 kgf·cm, 44 in·lbf}

5. INSTALL NO. 1 ENGINE UNDER COVER

Click here

.gif)

.gif)

6. INSTALL PUSH ROD PIN

Click here

.gif)

7. INSTALL BRAKE PEDAL RETURN SPRING

Click here

.gif)

8. INSTALL BRAKE MASTER CYLINDER SUB-ASSEMBLY

Click here

.gif)

9. INSPECT AND ADJUST BRAKE PEDAL

Click here

.gif)

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL VACUUM WARNING SWITCH ASSEMBLY

(a) Install a new check valve grommet to the brake booster assembly.

(b) Install the vacuum sensor assembly to the brake b ...

Brake Fluid

Brake Fluid

...

Other materials:

Toyota CH-R Service Manual > Front Lower Suspension Arm: Components

COMPONENTS

ILLUSTRATION

*1

NO. 1 ENGINE UNDER COVER

*2

REAR ENGINE UNDER COVER LH

N*m (kgf*cm, ft.*lbf): Specified torque

-

-

ILLUSTRATION

*1

FRONT LOWER NO. 1 SUSPENSIO ...

Toyota CH-R Service Manual > Repair Instruction: Precaution

PRECAUTION

BASIC REPAIR HINT

(a) HINTS ON OPERATIONS

1

Attire

Always wear a clean uniform.

A hat and safety shoes must be worn.

2

Vehicle protection

Prepare a grille cover, fender cover, seat cove ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0109