Toyota CH-R Service Manual: Security Indicator Light Does not Blink

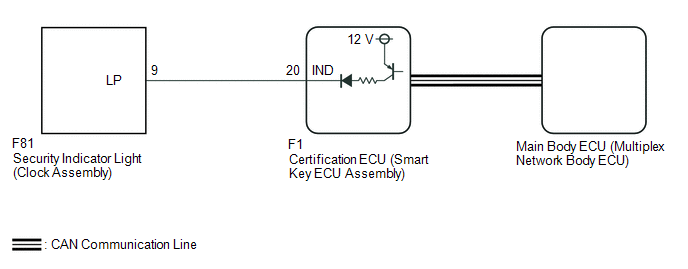

DESCRIPTION

The certification ECU (smart key ECU assembly) blinks the security indicator light (clock assembly) when the immobiliser is set (engine switch off).

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When using the Techstream with the engine switch off, connect the Techstream to the DLC3 and turn a courtesy light switch on and off at intervals of 1.5 seconds or less until communication between the Techstream and the vehicle begins. Then select the vehicle type under manual mode and enter the following menus: Body Electrical / Smart Key. While using the Techstream, periodically turn a courtesy light switch on and off at intervals of 1.5 seconds or less to maintain communication between the Techstream and the vehicle.

- Before replacing the certification ECU (smart key ECU assembly), refer

to Registration.

Click here

.gif)

PROCEDURE

|

1. |

CHECK FOR DTC |

(a) Check for DTCs.

Click here .gif)

OK:

DTCs are not output.

| NG | .gif) |

GO TO DIAGNOSTIC TROUBLE CODE CHART |

|

|

2. |

PERFORM ACTIVE TEST USING TECHSTREAM (IMMOBILISER INDICATOR) |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Smart Key / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Smart Key > Active Test|

Tester Display |

Measurement Item |

Type |

Diagnostic Note |

|---|---|---|---|

|

Immobiliser Indicator |

Security indicator light |

OFF/ON |

- |

|

Tester Display |

|---|

|

Immobiliser Indicator |

OK:

The security indicator light (clock assembly) operates normally.

| NG | .gif) |

GO TO STEP 4 |

|

|

3. |

CHECK SECURITY INDICATOR LIGHT (CLOCK ASSEMBLY) |

(a) When the immobiliser is set, check that the security indicator light (clock assembly) blinks.*1

OK:

The security indicator light (clock assembly) blinks normally.

(b) When the theft deterrent system is in the arming preparation state, check that the security indicator light (clock assembly) illuminates.*2

OK:

The security indicator light (clock assembly) illuminates normally.

|

Result |

Proceed to |

|---|---|

|

*1 is NG (*2 is OK) |

A |

|

*2 is NG (*1 is OK) |

B |

| A | .gif) |

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

| B | .gif) |

REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

|

4. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - SECURITY INDICATOR LIGHT (CLOCK ASSEMBLY)) |

(a) Disconnect the F1 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the F81 security indicator light (clock assembly) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F1-20 (IND) - F81-9 (LP) |

Always |

Below 1 Ω |

|

F1-20 (IND) or F81-9 (LP) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

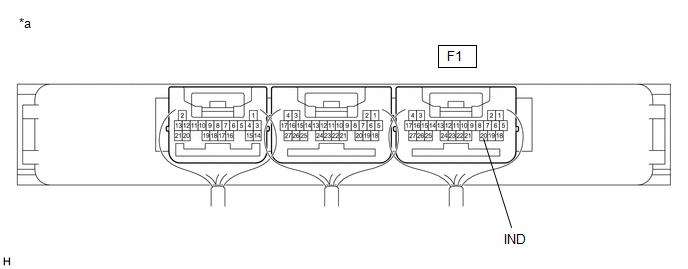

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

(a) Reconnect the F1 certification ECU (smart key ECU assembly) connector.

(b) Reconnect the F81 security indicator light (clock assembly) connector.

(c) Using an oscilloscope, check the waveform.

|

*a |

Component with harness connected (Certification ECU (Smart Key ECU Assembly)) |

- |

- |

Measurement Condition:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

F1-20 (IND) - Body ground |

Engine switch off → on (IG) |

Pulse generation → Below 2 V |

| OK | .gif) |

REPLACE SECURITY INDICATOR LIGHT (CLOCK ASSEMBLY)

|

| NG | .gif) |

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

Immobiliser System does not Operate Properly

Immobiliser System does not Operate Properly

DESCRIPTION

The immobiliser system compares the ID code that is registered to the certification

ECU (smart key ECU assembly) with the ID code of the transponder chip that is embedded

in the elect ...

Other materials:

Toyota CH-R Service Manual > Toyota Entune System: Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

Telematics System

DTC No.

Detection Item

Link

U0142

Lost Communication with Body Control Module "B"

U0155

Lost Communication with Instrument Panel Cl ...

Toyota CH-R Service Manual > Navigation System: Precaution

PRECAUTION

PRECAUTION FOR NAVIGATION SYSTEM

NOTICE:

When replacing the radio and display receiver assembly or navigation

ECU, always replace it with a new one. If a radio and display receiver assembly

or navigation ECU which was installed to another vehicle is used, the following ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0101

.gif)