Toyota CH-R Service Manual: Rear Seat Belt Warning Light Malfunction

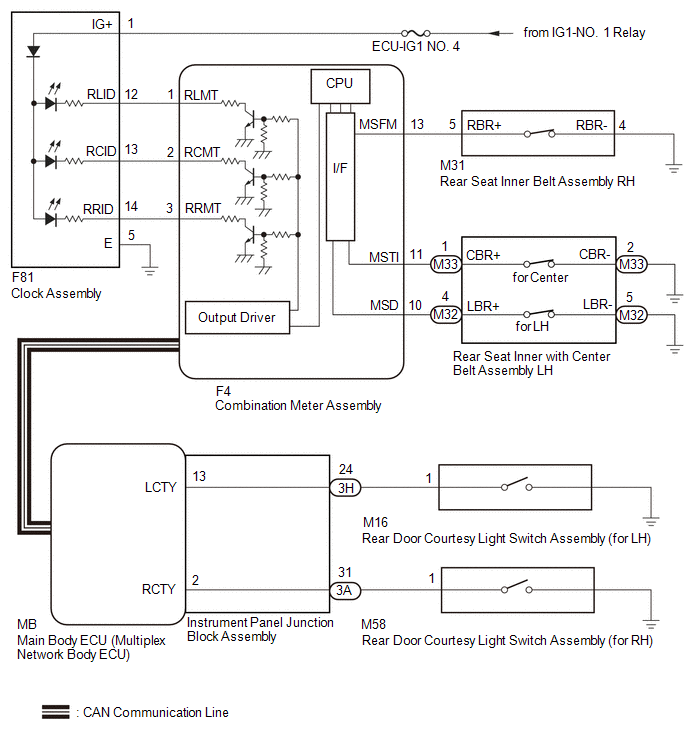

DESCRIPTION

The main body ECU (multiplex network body ECU) detects whether either the rear doors are open or closed based on the condition of the rear door courtesy light switch assemblies condition and then sends the rear door status signal to the combination meter assembly. The combination meter assembly detects rear seat belt state. The rear seat belt warning light on the clock assembly illuminates or turns off in accordance with the rear door state, vehicle speed and rear seat belt state.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- The seat belt warning system uses the CAN communication system. First,

confirm that there is no malfunction in the CAN communication system. Refer

to the How to Proceed with Troubleshooting procedure.

Click here

.gif)

- When replacing the combination meter assembly, always replace it with a new one. If a combination meter assembly which was installed to another vehicle is used, the information stored in it will not match the information from the vehicle and a DTC may be stored.

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (REAR DOOR COURTESY LIGHT SWITCH) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Main Body > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

RR Door Courtesy SW |

Rear door courtesy light switch RH |

ON or OFF |

ON: Rear door RH open OFF: Rear door RH closed |

- |

|

RL Door Courtesy SW |

Rear door courtesy light switch LH |

ON or OFF |

ON: Rear door LH open OFF: Rear door LH closed |

- |

|

Tester Display |

|---|

|

RR Door Courtesy SW |

|

RL Door Courtesy SW |

OK:

ON or OFF appears on the Techstream screen according to the rear door condition.

| NG | .gif) |

GO TO LIGHTING SYSTEM |

|

|

2. |

READ VALUE USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Combination Meter / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Combination Meter > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

2nd-Row Seatbelt Buckle (R) |

Rear RH seat belt buckle switch signal |

ON or OFF |

ON: Rear RH seat belt not fastened OFF: Rear RH seat belt fastened |

- |

|

2nd-Row Seatbelt Buckle (L) |

Rear LH seat belt buckle switch signal |

ON or OFF |

ON: Rear LH seat belt not fastened OFF: Rear LH seat belt fastened |

- |

|

2nd-Row Seatbelt Buckle (C) |

Rear center seat belt buckle switch signal |

ON or OFF |

ON: Rear center seat belt not fastened OFF: Rear center seat belt fastened |

- |

|

Tester Display |

|---|

|

2nd-Row Seatbelt Buckle (R) |

|

2nd-Row Seatbelt Buckle (L) |

|

2nd-Row Seatbelt Buckle (C) |

OK:

The Techstream display changes correctly in response to the rear door condition.

|

Result |

Proceed to |

|---|---|

|

ON or OFF is displayed on the Techstream screen according to the rear seat belt condition |

A |

|

ON or OFF is not displayed normally on the Techstream screen according to the rear LH seat belt condition |

B |

|

ON or OFF is not displayed normally on the Techstream screen according to the rear center seat belt condition |

B |

|

ON or OFF is not displayed normally on the Techstream screen according to the rear RH seat belt condition |

C |

| B | .gif) |

GO TO STEP 6 |

| C | .gif) |

GO TO STEP 8 |

|

|

3. |

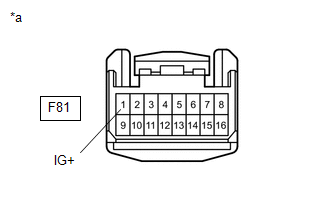

CHECK HARNESS AND CONNECTOR (CLOCK ASSEMBLY - BATTERY) |

|

(a) Disconnect the clock assembly connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

F81-1 (IG+) - Body ground |

Ignition switch ON |

11 to 14 V |

|

Ignition switch off |

Below 1 V |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

INSPECT CLOCK ASSEMBLY |

(a) Remove the clock assembly.

Click here .gif)

.gif)

(b) Inspect the clock assembly.

Click here .gif)

.gif)

| NG | .gif) |

REPLACE CLOCK ASSEMBLY |

|

|

5. |

CHECK HARNESS AND CONNECTOR (CLOCK ASSEMBLY - COMBINATION METER ASSEMBLY) |

(a) Disconnect the F81 clock assembly connector.

(b) Disconnect the F4 combination meter assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F81-12 (RLID) - F4-1 (RLMT) |

Always |

Below 1 Ω |

|

F81-13 (RCID) - F4-2 (RCMT) |

Always |

Below 1 Ω |

|

F81-14 (RRID) - F4-3 (RRMT) |

Always |

Below 1 Ω |

|

F81-12 (RLID) or F4-1 (RLMT) - Body ground |

Always |

10 kΩ or higher |

|

F81-13 (RCID) or F4-2 (RCMT) - Body ground |

Always |

10 kΩ or higher |

|

F81-14 (RRID) or F4-3 (RRMT) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

6. |

INSPECT REAR SEAT INNER WITH CENTER BELT ASSEMBLY LH |

(a) Remove the rear seat inner with center belt assembly LH.

Click here .gif)

.gif)

(b) Inspect the rear seat inner with center belt assembly LH.

Click here .gif)

.gif)

| NG | .gif) |

REPLACE REAR SEAT INNER WITH CENTER BELT ASSEMBLY LH

|

|

|

7. |

CHECK HARNESS AND CONNECTOR (REAR SEAT INNER WITH CENTER BELT ASSEMBLY LH - COMBINATION METER ASSEMBLY AND BODY GROUND) |

(a) Disconnect the M32 and M33 rear seat inner with center belt assembly LH connectors.

(b) Disconnect the F4 combination meter assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

M32-4 (LBR+) - F4-10 (MSD) |

Always |

Below 1 Ω |

|

M33-1 (CBR+) - F4-11 (MSTI) |

Always |

Below 1 Ω |

|

M32-5 (LBR-) - Body ground |

Always |

Below 1 Ω |

|

M33-2 (CBR-) - Body ground |

Always |

Below 1 Ω |

|

M32-4 (LBR+) or F4-10 (MSD) - Body ground |

Always |

10 kΩ or higher |

|

M33-1 (CBR+) or F4-11 (MSTI) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

8. |

INSPECT REAR SEAT INNER BELT ASSEMBLY RH |

(a) Remove the rear seat inner belt assembly RH.

Click here .gif)

.gif)

(b) Inspect the rear seat inner belt assembly RH.

Click here .gif)

.gif)

| NG | .gif) |

REPLACE REAR SEAT INNER BELT ASSEMBLY RH

|

|

|

9. |

CHECK HARNESS AND CONNECTOR (REAR SEAT INNER BELT ASSEMBLY RH - COMBINATION METER ASSEMBLY AND BODY GROUND) |

(a) Disconnect the M31 rear seat inner belt assembly RH connector.

(b) Disconnect the F4 combination meter assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

M31-5 (RBR+) - F4-13 (MSFM) |

Always |

Below 1 Ω |

|

M31-4 (RBR-) - Body ground |

Always |

Below 1 Ω |

|

M31-5 (RBR+) or F4-13 (MSFM) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Front Passenger Side Seat Belt Warning Light Malfunction

Front Passenger Side Seat Belt Warning Light Malfunction

DESCRIPTION

When the ignition switch is turned ON, the occupant detection ECU sends signals

to the airbag sensor assembly to indicate the state of the front seat inner belt

assembly RH and also w ...

Other materials:

Toyota CH-R Service Manual > Audio And Visual System(for Radio And Display Type): Data Signal Circuit between Radio Receiver and Stereo Jack Adapter

DESCRIPTION

The No. 1 stereo jack adapter assembly sends the sound data signal or image data

signal from a USB device to the radio and display receiver assembly via this circuit.

WIRING DIAGRAM

PROCEDURE

1.

CHECK HARNESS AND CONNECTOR (RADIO AND DISPLAY RECEIVER ASSEMB ...

Toyota CH-R Service Manual > Continuously Variable Transaxle Assembly(when Using The Engine Support Bridge): Installation

INSTALLATION

CAUTION / NOTICE / HINT

PROCEDURE

1. INSTALL TRANSMISSION BREATHER HOSE SUB-ASSEMBLY

HINT:

Perform this procedure only when replacement of the transmission breather hose

sub-assembly is necessary.

(a) Apply Toyota Genuine CVT fluid FE to a new O-ring, and install it to the

No. ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0085

.gif)