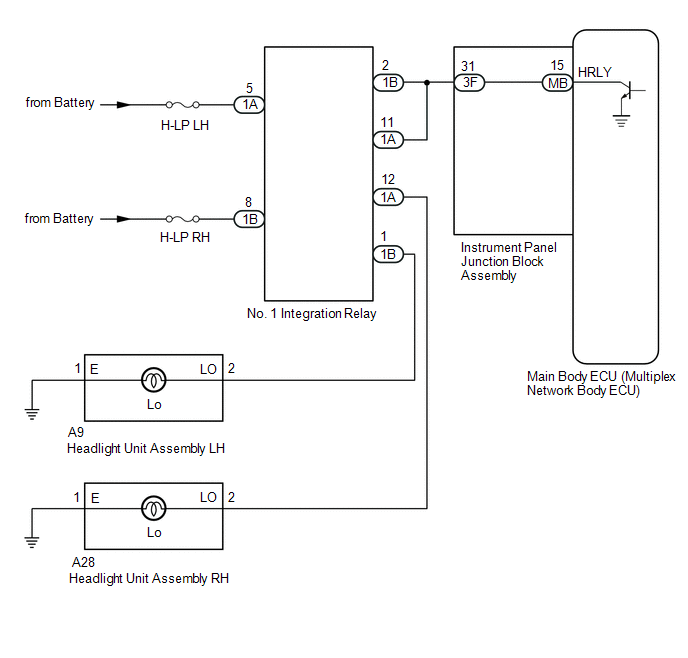

Toyota CH-R Service Manual: Low Beam Headlight Circuit

DESCRIPTION

The main body ECU (multiplex network body ECU) controls the low beam headlights.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses and bulbs for circuits related to this system before performing the following procedure.

- Before replacing the main body ECU (multiplex network body ECU), refer

to Registration.*1

Click here

.gif)

- *1: w/ Smart Key System

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM (HEADLIGHT RELAY) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Active Test.

(e) Check that the relay operates.

Body Electrical > Main Body > Active Test|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Headlight Relay |

Low beam headlights |

ON or OFF |

- |

|

Tester Display |

|---|

|

Headlight Relay |

OK:

Headlight relay operates. (Low beam headlights illuminate.)

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE

|

|

|

2. |

INSPECT NO. 1 INTEGRATION RELAY (H-LP LH RELAY, H-LP RH RELAY) |

(a) Remove the No. 1 integration relay from the No. 1 engine room relay block.

Click here

.gif)

(b) Inspect the No. 1 integration relay.

Click here

.gif)

OK:

No. 1 integration relay is normal.

| NG | .gif) |

REPLACE NO. 1 INTEGRATION RELAY |

|

|

3. |

CHECK HARNESS AND CONNECTOR (NO. 1 INTEGRATION RELAY - BATTERY) |

(a) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1A-5 - Body ground |

Always |

11 to 14 V |

|

1B-8 - Body ground |

Always |

11 to 14 V |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK HARNESS AND CONNECTOR (NO. 1 INTEGRATION RELAY - HEADLIGHT ASSEMBLY LH AND HEADLIGHT ASSEMBLY RH AND BODY GROUND) |

(a) Disconnect the A9 headlight assembly LH connector.

(b) Disconnect the A28 headlight assembly RH connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1B-1 - A9-2 (LO) |

Always |

Below 1 Ω |

|

1A-12 - A28-2 (LO) |

Always |

Below 1 Ω |

|

A9-1 (E) - Body ground |

Always |

Below 1 Ω |

|

A28-1 (E) - Body ground |

Always |

Below 1 Ω |

|

1B-1 - Body ground |

Always |

10 kΩ or higher |

|

1A-12 - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

CHECK HARNESS AND CONNECTOR (NO. 1 INTEGRATION RELAY - INSTRUMENT PANEL JUNCTION BLOCK) |

(a) Disconnect the 3F instrument panel junction block assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1A-11 - 3F-31 |

Always |

Below 1 Ω |

|

1B-2 - 3F-31 |

Always |

Below 1 Ω |

|

1A-11 or 3F-31 - Body ground |

Always |

10 kΩ or higher |

|

1B-2 or 3F-31 - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

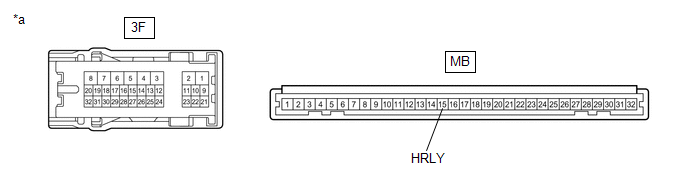

6. |

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

(a) Remove the instrument panel junction block assembly.

Click here

.gif)

.gif)

(b) Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly.

(c) Measure the resistance according to the value(s) in the table below.

|

*a |

Component without harness connected (Instrument Panel Junction Block Assembly) |

- |

- |

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3F-31 - MB-15 (HRLY) |

Always |

Below 1 Ω |

| OK | .gif) |

REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)

|

| NG | .gif) |

REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

|

Power Source Circuit

Power Source Circuit

DESCRIPTION

When the ignition switch is ON or the operation conditions of the headlights

are met, the main body ECU (multiplex network body ECU) supplies power to the headlight

ECU sub-assemblies ...

High Beam Headlight Circuit

High Beam Headlight Circuit

DESCRIPTION

The main body ECU (multiplex network body ECU) controls the high beam headlights.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuse for circuits related to thi ...

Other materials:

Toyota CH-R Service Manual > Rear Door Window Frame Moulding: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration)

that must be performed after parts are removed and installed, or replaced during

the rear door window frame moulding removal/installation are shown below.

Necessary Procedure Af ...

Toyota CH-R Service Manual > Brake Actuator: Components

COMPONENTS

ILLUSTRATION

*1

COWL BODY MOUNTING REINFORCEMENT LH

*2

COWL BODY MOUNTING REINFORCEMENT RH

*3

NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

*4

OUTER COWL TOP PANEL SUB-ASSEMBLY

*5 ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0094

.gif)