Toyota CH-R Service Manual: Height Control Sensor Malfunction (B2416,B241A)

DESCRIPTION

This DTC is stored when the headlight ECU sub-assembly LH detects a malfunction in the rear height control sensor sub-assembly LH power source circuit or rear height control sensor sub-assembly LH circuit. The headlight ECU sub-assembly LH stores DTC B2416 and B241A.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

Note |

|---|---|---|---|---|

|

B2416 |

Height Control Sensor Malfunction |

Any of the following conditions is met:

|

|

- |

|

B241A |

Rear Height Control Sensor |

Any of the following conditions is met:

|

|

- |

|

Vehicle Condition |

||||

|---|---|---|---|---|

|

Pattern 1 |

Pattern 2 |

Pattern 3 |

||

|

Diagnosis Condition |

Ignition switch ON |

○ |

○ |

○ |

|

Malfunction Status |

Malfunction in rear height control sensor sub-assembly LH |

○ |

- |

- |

|

Open in rear height control sensor sub-assembly LH power source circuit |

- |

○ |

- |

|

|

Short in rear height control sensor sub-assembly LH power source circuit |

- |

- |

○ |

|

|

Detection Time |

- |

- |

- |

|

|

Number of Trips |

1 trip |

1 trip |

1 trip |

|

HINT:

DTC will be output when conditions for either of the patterns in the table above are met.

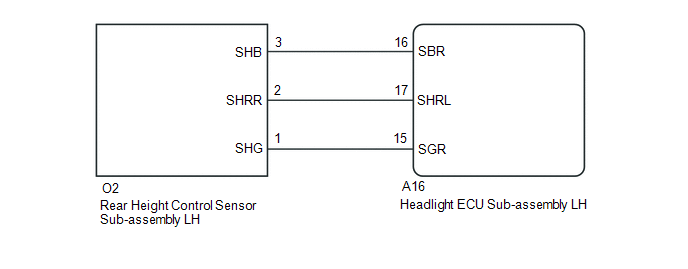

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Before performing this inspection, check that the rear height control sensor sub-assembly LH is installed correctly.

- If the headlight ECU sub-assembly LH has been replaced, it is necessary

to synchronize the vehicle information and initialize the headlight ECU

sub-assembly LH.

Click here

.gif)

- If any of the following are performed, it is necessary to initialize

the headlight ECU sub-assembly LH.

Click here

.gif)

- Replacement of the rear height control sensor sub-assembly LH

- Removal/installation of the rear height control sensor sub-assembly LH

- Work that changes the vehicle height such as replacement of suspension components

PROCEDURE

|

1. |

CLEAR DTC |

(a) Clear the DTCs.

Click here

.gif)

|

|

2. |

CHECK FOR DTC |

(a) Check for DTCs.

Click here

.gif)

OK:

DTC B2416 or B241A are not output.

| OK | .gif) |

USE SIMULATION METHOD TO CHECK

|

|

|

3. |

READ VALUE USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / HL AutoLeveling / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > HL AutoLeveling > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Height Sens Pw Supply Val |

Rear height control sensor sub-assembly LH power supply value |

0 to 5.00 V |

4.61 to 5.00 V |

- |

|

Rr Height Sens Signal Val |

Rear height control sensor sub-assembly LH signal value |

0 to 5.00 V |

0.50 to 4.50 V |

Value changes according to vehicle height |

|

Tester Display |

|---|

|

Height Sens Pw Supply Val |

|

Rr Height Sens Signal Val |

OK:

Normal condition listed above is displayed.

| OK | .gif) |

REPLACE HEADLIGHT ECU SUB-ASSEMBLY LH |

|

|

4. |

CHECK HARNESS AND CONNECTOR (HEADLIGHT ECU SUB-ASSEMBLY LH - REAR HEIGHT CONTROL SENSOR SUB-ASSEMBLY LH) |

(a) Disconnect the A16 headlight ECU sub-assembly LH connector.

(b) Disconnect the O2 rear height control sensor sub-assembly LH connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A16-16 (SBR) - O2-3 (SHB) |

Always |

Below 1 Ω |

|

A16-17 (SHRL) - O2-2 (SHRR) |

Always |

Below 1 Ω |

|

A16-15 (SGR) - O2-1 (SHG) |

Always |

Below 1 Ω |

|

A16-16 (SBR) or O2-3 (SHB) - Body ground |

Always |

10 kΩ or higher |

|

A16-17 (SHRL) or O2-2 (SHRR) - Body ground |

Always |

10 kΩ or higher |

|

A16-15 (SGR) or O2-1 (SHG) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

INSPECT REAR HEIGHT CONTROL SENSOR SUB-ASSEMBLY LH |

(a) Remove the rear height control sensor sub-assembly LH.

Click here

.gif)

(b) Inspect the rear height control sensor sub-assembly LH.

Click here

.gif)

OK:

Rear height control sensor sub-assembly LH is normal.

| OK | .gif) |

REPLACE HEADLIGHT ECU SUB-ASSEMBLY LH |

| NG | .gif) |

REPLACE REAR HEIGHT CONTROL SENSOR SUB-ASSEMBLY LH |

Vehicle Speed Sensor Malfunction (B2415)

Vehicle Speed Sensor Malfunction (B2415)

DESCRIPTION

The headlight ECU sub-assembly LH receives signals indicating the vehicle speed

signal from the brake actuator assembly (skid control ECU) using CAN communication.

The headlight ECU s ...

Automatic High Beam Main Switch

Automatic High Beam Main Switch

Components

COMPONENTS

ILLUSTRATION

*1

AUTO HIGH BEAM SWITCH

*2

INSTRUMENT CLUSTER FINISH PANEL SUB-ASSEMBLY

Removal

REMOVAL

PROCEDURE

...

Other materials:

Toyota CH-R Service Manual > Rear Seat Side Airbag Assembly: Disposal

DISPOSAL

CAUTION / NOTICE / HINT

CAUTION:

Before performing pre-disposal deployment of any SRS part, review and closely

follow all applicable environmental and hazardous material regulations. Pre-disposal

deployment may be considered hazardous material treatment.

HINT:

Use the same ...

Toyota CH-R Service Manual > Occupant Classification System: Yaw Rate Sensor Module Malfunction (B1798,B1799)

DESCRIPTION

The occupant detection ECU receives signals from the acceleration sensor (airbag

sensor assembly) and skid control ECU via CAN communication.

DTC No.

Detection Item

DTC Detection Condition

Trouble Area

B1798

Yaw ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0089

.gif)