Toyota CH-R Service Manual: Inspection

INSPECTION

PROCEDURE

1. INSPECT PRELOAD

|

(a) Secure the steering column assembly in a vise using aluminum plates, cloths and wooden blocks. NOTICE:

|

|

|

(b) Install 2 service nuts to the steering main shaft. Recommended Service Nut: Thread Diameter 12.0 mm (0.472 in.) Thread Pitch 1.25 mm (0.0492 in.) |

|

(c) Simultaneously rotate the service nut that was installed first counterclockwise and rotate the service nut that was installed second clockwise to lock them.

NOTICE:

Do not apply excessive torque to the service nuts by using a tool such as an impact wrench.

HINT:

The service nuts are used for turning the steering main shaft during inspection of the steering main shaft rotating torque.

Remove the service nuts after performing this inspection.

|

(d) Using a torque wrench, turn the steering main shaft at a constant rate of approximately 1 revolution every 4 seconds and measure the preload. Preload: 1.2 to 2.4 N*m (13 to 24 kgf*cm, 11 to 21 in.*lbf) If the preload is not as specified, replace the power steering ECU assembly or electric power steering column sub-assembly with a new one. |

|

(e) Remove the 2 service nuts.

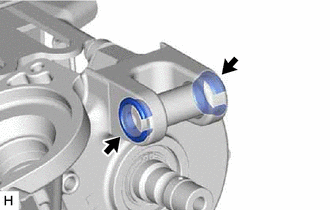

2. INSPECT STEERING COLUMN ASSEMBLY

|

(a) Check that the 2 bushings are securely installed to the steering column assembly. If the bushings are deformed, missing or damaged, replace the electric power steering column sub-assembly with a new one. |

|

Disassembly

Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

NOTICE:

Do not drop the power steering ECU assembly, strike it with tools or

subject it to impacts.

If the power steering ECU assembly is subject ...

Installation

Installation

INSTALLATION

PROCEDURE

1. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

2. INSTALL STEERING COLUMN ASSEMBLY

NOTICE:

Make sure that the wire harness is not interfering with the steering column assembly ...

Other materials:

Toyota CH-R Service Manual > Audio And Visual System(for Radio Receiver Type): Cellular Phone Inspection

CAUTION / NOTICE / HINT

HINT:

If the operation of a cellular phone or the radio receiver assembly is requested,

make sure to follow the instructions closely and perform the operation.

PROCEDURE

1.

CHECK USAGE CONDITION

(a) Check that the vehicle and cellular ph ...

Toyota CH-R Service Manual > Audio And Visual System(for Radio And Display Type): USB Audio System Recognition/Play Error

DESCRIPTION

When a USB device or "iPod" is connected to the USB jack of the No. 1 stereo

jack adapter assembly, it must have playable files. The device must also communicate

with and be recognized by the radio and display receiver assembly. This diagnostic

procedure is for when a de ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.008

.png)

.png)

.png)