Toyota CH-R Service Manual: Torque Sensor1 (C1511-C1514,C1517)

DESCRIPTION

The torque sensor converts the rotational torque received from the steering wheel into electric signals and sends them to the power steering ECU assembly.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

Warning Indicate |

Return-to-normal Condition |

Note |

|---|---|---|---|---|---|---|

|

C1511 |

Torque Sensor1 |

Torque sensor malfunction |

|

EPS warning light: Comes on |

The ECU judges the system has returned to normal or the ignition switch ON again |

- |

|

C1512 |

Torque Sensor2 |

Torque sensor malfunction |

|

EPS warning light: Comes on |

The ECU judges the system has returned to normal or the ignition switch ON again |

- |

|

C1513 |

Torque Sensor Deviation Excessive |

Torque sensor malfunction |

|

EPS warning light: Comes on |

The ECU judges the system has returned to normal or the ignition switch ON again |

- |

|

C1514 |

Torque Sensor Power Supply Voltage |

Torque sensor malfunction |

|

EPS warning light: Comes on |

Ignition switch ON again |

- |

|

C1517 |

Torque Hold |

Torque sensor malfunction |

|

EPS warning light: Comes on |

Ignition switch ON again |

- |

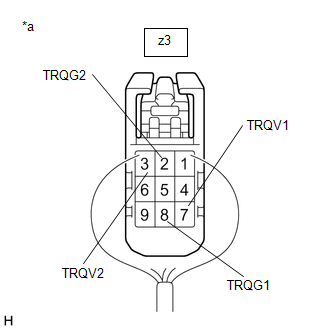

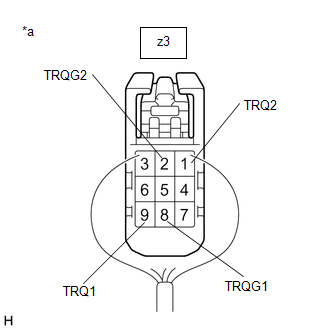

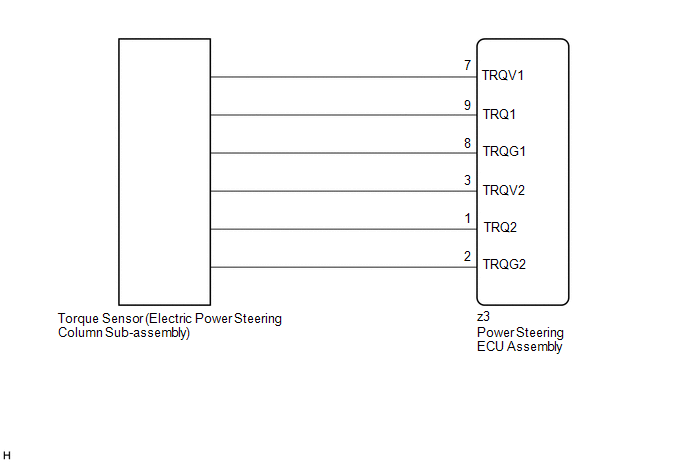

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- If the electric power steering column sub-assembly has been replaced,

perform torque sensor zero point calibration.

Click here

.gif)

- If the power steering ECU assembly has been replaced, perform assist

map writing and torque sensor zero point calibration.

Click here

.gif)

PROCEDURE

|

1. |

CHECK CONNECTOR CONNECTION CONDITION |

(a) Check the connection condition of the torque sensor connector.

OK:

Torque sensor connector is securely connected to the power steering ECU assembly.

| NG | .gif) |

CONNECT CONNECTOR |

|

|

2. |

CHECK POWER STEERING ECU ASSEMBLY (TRQV VOLTAGE) |

|

(a) Turn the ignition switch to ON. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

z3-7 (TRQV1) - z3-8 (TRQG1) |

Ignition switch ON |

4.5 to 5.5 V |

|

z3-3 (TRQV2) - z3-2 (TRQG2) |

Ignition switch ON |

4.5 to 5.5 V |

| NG | .gif) |

REPLACE POWER STEERING ECU ASSEMBLY |

|

|

3. |

CHECK POWER STEERING ECU ASSEMBLY (TRQ1, TRQ2 VOLTAGE) |

|

(a) Turn the engine running. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

z3-9 (TRQ1) - z3-8 (TRQG1) |

Engine running and steering wheel not being turned (without load) |

2.3 to 2.7 V |

|

Engine running and steering wheel being turned to the right with vehicle stopped |

2.5 to 3.8 V |

|

|

Engine running and steering wheel being turned to the left with vehicle stopped |

1.2 to 2.5 V |

|

|

z3-1 (TRQ2) - z3-2 (TRQG2) |

Engine running and steering wheel not being turned (without load) |

2.3 to 2.7 V |

|

Engine running and steering wheel being turned to the right with vehicle stopped |

1.2 to 2.5 V |

|

|

Engine running and steering wheel being turned to the left with vehicle stopped |

2.5 to 3.8 V |

(c) Under each condition, measure the voltage at terminals TRQ1 and TRQ2, and calculate the sum.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Sum of voltage between z3-9 (TRQ1) and z3-8 (TRQG1) and voltage between z3-1 (TRQ2) and z3-2 (TRQG2) |

Engine running and steering wheel not being turned (without load) |

Between 4.75 V and 5.25 V |

|

Engine running and steering wheel being turned to the right with vehicle stopped |

||

|

Engine running and steering wheel being turned to the left with vehicle stopped |

| OK | .gif) |

REPLACE POWER STEERING ECU ASSEMBLY |

| NG | .gif) |

REPLACE ELECTRIC POWER STEERING COLUMN SUB-ASSEMBLY |

PIG Power Supply Voltage (C1552,C1554)

PIG Power Supply Voltage (C1552,C1554)

DESCRIPTION

If a problem occurs in the system, the power source relay circuit and the motor

relay circuit are shut off to stop power assist. The ECU must be replaced when there

is a problem with ...

Torque Sensor Zero Point Adjustment Undone (C1515)

Torque Sensor Zero Point Adjustment Undone (C1515)

DESCRIPTION

This DTC does not indicate a malfunction. The power steering ECU assembly stores

this DTC when it determines that torque sensor zero point calibration has not been

performed.

...

Other materials:

Toyota CH-R Service Manual > Stop Light Switch: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration)

that must be performed after parts are removed and installed, or replaced during

the stop light switch assembly removal/installation are shown below.

Necessary Procedures after p ...

Toyota CH-R Service Manual > Meter / Gauge System: Washer Fluid Level Warning Switch Circuit

DESCRIPTION

The combination meter assembly and level warning switch assembly are connected

via direct line. The combination meter assembly determines the washer fluid level

and outputs warning messages according to the washer fluid level warning switch

ON/OFF signal.

WIRING DIAGRAM

CAUTIO ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0066

.gif)