Toyota CH-R Service Manual: Inspection

INSPECTION

PROCEDURE

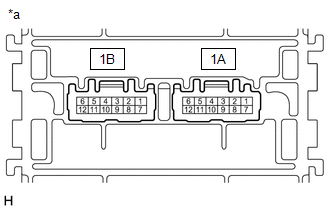

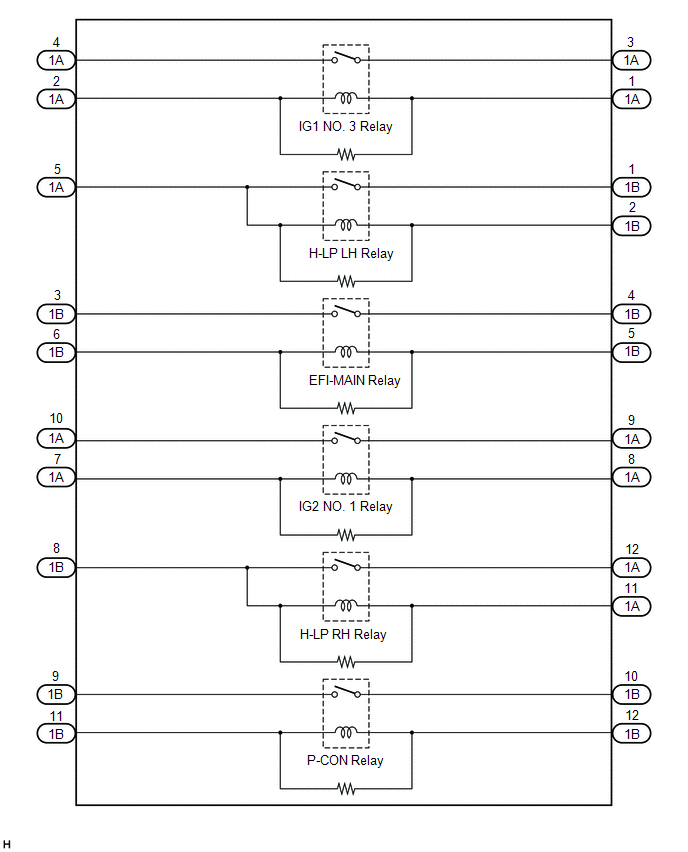

1. INSPECT NO. 1 INTEGRATION RELAY

(a) IG1 NO. 3 RELAY:

|

(1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the No. 1 integration relay. |

|

(b) H-LP LH RELAY:

|

(1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the No. 1 integration relay. |

|

(c) EFI-MAIN RELAY:

|

(1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the No. 1 integration relay. |

|

(d) IG2 NO. 1 RELAY:

|

(1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the No. 1 integration relay. |

|

(e) H-LP RH RELAY:

|

(1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the No. 1 integration relay. |

|

(f) P-CON RELAY:

|

(1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the No. 1 integration relay. |

|

Components

Components

COMPONENTS

ILLUSTRATION

*1

NO. 1 INTEGRATION RELAY

*2

NO. 1 RELAY BLOCK COVER

...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration)

that must be performed after parts are removed and installed, or replaced during ...

Other materials:

Toyota CH-R Service Manual > Front Seat Assembly: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration)

that must be performed after parts are removed, installed, or replaced during the

front seat assembly removal/installation are shown below.

Necessary Procedure After Parts Remov ...

Toyota CH-R Service Manual > Exterior Panels / Trim: Roof Drip Side Finish Moulding

Components

COMPONENTS

ILLUSTRATION

*1

CENTER ROOF DRIP SIDE FINISH MOULDING

*2

NO. 1 ROOF DRIP SIDE FINISH MOULDING CLIP

●

Non-reusable part

-

-

Removal

REMOVAL

CAUTION / NOTICE / HIN ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0089