Toyota CH-R Service Manual: Reassembly

REASSEMBLY

PROCEDURE

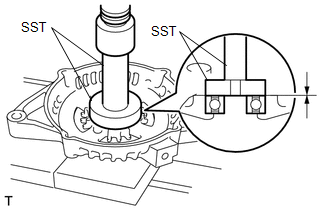

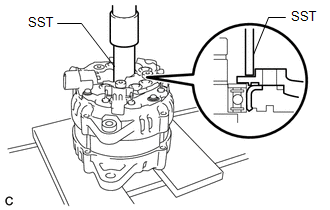

1. INSTALL GENERATOR DRIVE END FRAME BEARING

|

(a) Using SST and a press, install a new generator drive end frame bearing. SST: 09950-60010 09951-00470 SST: 09950-70010 09951-07100 |

|

|

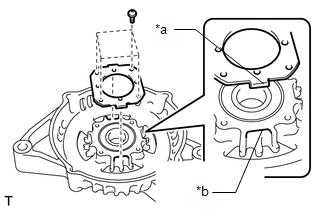

(b) Fit the tabs of the retainer plate into the cutouts of the generator drive end frame to install the retainer plate. |

|

(c) Install the 4 screws.

Torque:

2.3 N·m {23 kgf·cm, 20 in·lbf}

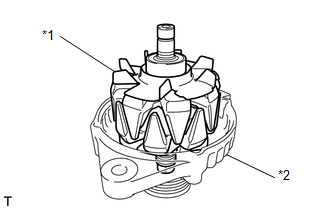

2. INSTALL GENERATOR ROTOR ASSEMBLY

|

(a) Place the generator drive end frame on the generator pulley with clutch. |

|

(b) Install the generator rotor assembly to the generator drive end frame.

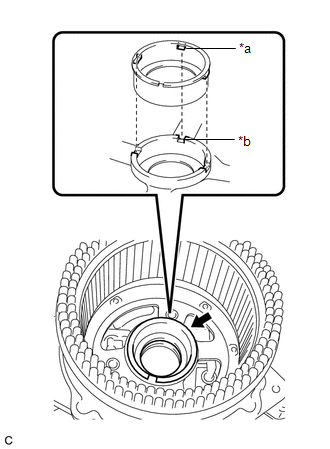

3. INSTALL GENERATOR COIL ASSEMBLY

|

(a) Install a new bearing cover packing. NOTICE: Align the protrusions of the bearing cover packing with the grooves of the generator coil assembly when installing. |

|

|

(b) Using SST and a press, slowly press the generator coil assembly to install it. SST: 09612-70100 09612-07240 |

|

(c) Install the 4 bolts.

Torque:

5.9 N·m {60 kgf·cm, 52 in·lbf}

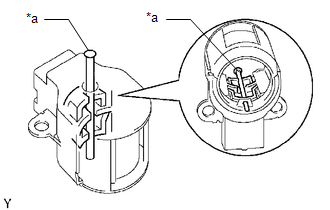

4. INSTALL GENERATOR BRUSH HOLDER ASSEMBLY

|

(a) While pushing the 2 brushes into the generator brush holder assembly, insert a 1.0 mm (0.0394 in.) pin into the generator brush holder assembly hole. |

|

|

(b) Install the generator brush holder assembly to the generator coil assembly with the 2 screws. Torque: 1.8 N·m {18 kgf·cm, 16 in·lbf} |

|

(c) Pull out the pin from the generator brush holder assembly hole.

5. INSTALL GENERATOR TERMINAL INSULATOR

(a) Install the generator terminal insulator to the generator coil assembly.

NOTICE:

Be sure to install the generator terminal insulator in the correct direction.

6. INSTALL GENERATOR REAR END COVER

(a) Install the generator rear end cover to the generator coil assembly with the 3 bolts.

Torque:

4.6 N·m {47 kgf·cm, 41 in·lbf}

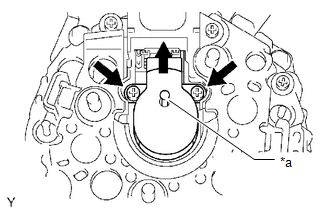

7. INSTALL GENERATOR PULLEY WITH CLUTCH

(a) Secure the generator drive end frame in a vise between aluminum plates.

(b) Temporarily install the generator pulley with clutch to the rotor shaft.

|

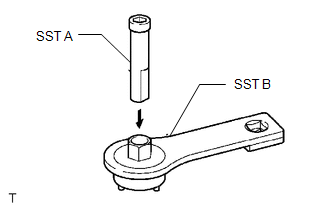

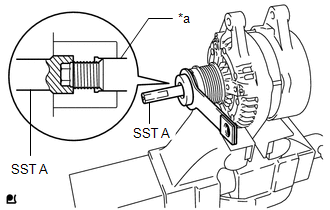

(c) Confirm SST (A) and (B) shown in the illustration. SST: 09820-63021 |

|

|

(d) Place the rotor shaft end into SST (A). |

|

|

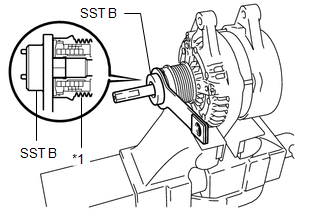

(e) Fit SST (B) to the generator pulley with clutch. |

|

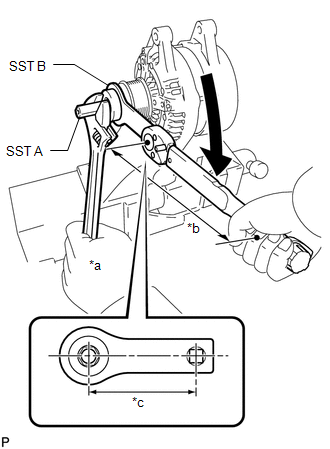

(f) Tighten the generator pulley with clutch by turning SST (B) as shown in the illustration.

|

*a |

Hold |

|

*b |

Torque Wrench Fulcrum Length |

|

*c |

SST Fulcrum Length |

.png) |

Turn |

Torque:

Specified tightening torque :

80 N·m {816 kgf·cm, 59 ft·lbf}

NOTICE:

Be careful as the generator pulley with clutch or rotor shaft may be damaged if the position of SST is not securely maintained while performing this operation.

HINT:

- Calculate the torque wrench reading when changing the fulcrum length

of the torque wrench.

Click here

.gif)

.gif)

- When using SST (fulcrum length of 100 mm (3.94 in.)) + torque wrench (fulcrum length of 400 mm (15.7 in.)): 64 N*m (653 kgf*cm, 47 ft.*lbf)

(g) Remove SST from the generator pulley with clutch.

(h) Check that the generator pulley with clutch rotates smoothly.

(i) Remove the generator drive end frame from the vise.

8. INSTALL GENERATOR PULLEY CAP

(a) Install a new generator pulley cap to the generator pulley with clutch.

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL GENERATOR ASSEMBLY

(a) Install the wire harness clamp bracket to the generator assembly with the

bolt.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

( ...

Networking

Networking

...

Other materials:

Toyota CH-R Service Manual > Safety Connect System: Dcm Power Source Circuit

DESCRIPTION

This is the power source circuit to operate the DCM (Telematics Transceiver).

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following

procedure.

PROCEDURE

1.

CHECK HARNESS AND C ...

Toyota CH-R Service Manual > Smart Key System(for Start Function): Customize Parameters

CUSTOMIZE PARAMETERS

CUSTOMIZE SMART KEY SYSTEM (for Start Function)

NOTICE:

When the customer requests a change in a function, first make sure that

the function can be customized.

Record the current settings before customizing.

HINT:

The following items can be customized. ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0079