Toyota CH-R Service Manual: Short to GND in Immobiliser System Power Source Circuit (B278A)

DESCRIPTION

When there is a short to GND in the power supply for the transponder key amplifier of the engine switch, the certification ECU (smart key ECU assembly) stores this DTC.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

Note |

|---|---|---|---|---|

|

B278A |

Short to GND in Immobiliser System Power Source Circuit |

A short to GND in the power supply of the transponder key amplifier of the engine switch (VC5 - VC5) detected. (1 trip detection logic*1) |

|

DTC output confirmation operation:

|

- *1: Only output while a malfunction is present.

|

Vehicle Condition when Malfunction Detected |

Fail-safe Operation when Malfunction Detected |

|---|---|

|

Engine cannot be started when transmitter battery is depleted by holding transmitter near engine switch and pressing and holding engine switch with shift lever in P |

- |

|

DTC No. |

Data List and Active Test |

|---|---|

|

B278A |

- |

WIRING DIAGRAM

Refer to B2784.

Click here .gif)

CAUTION / NOTICE / HINT

NOTICE:

- When using the Techstream with the engine switch off, connect the Techstream to the DLC3 and turn a courtesy light switch on and off at intervals of 1.5 seconds or less until communication between the Techstream and the vehicle begins. Then select the vehicle type under manual mode and enter the following menus: Body Electrical / Smart Key. While using the Techstream, periodically turn a courtesy light switch on and off at intervals of 1.5 seconds or less to maintain communication between the Techstream and the vehicle.

- Before replacing the certification ECU (smart key ECU assembly), refer

to Registration.

Click here

.gif)

- After performing repairs, confirm that no DTCs are output by performing "DTC Output Confirmation Operation".

PROCEDURE

|

1. |

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

(a) Using an oscilloscope, check the waveform.

|

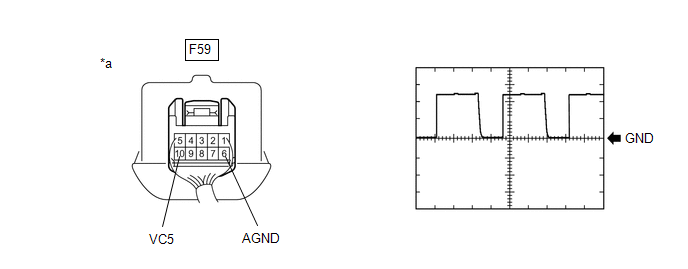

*a |

Component with harness connected (Engine Switch) |

- |

- |

HINT:

Perform this inspection on the engine switch side.

Measurement Condition:

|

Tester Connection |

Condition |

Tool Setting |

Specified Condition |

|---|---|---|---|

|

F59-10 (VC5) - F59-6 (AGND) |

Engine switch off, electrical key transmitter sub-assembly not in cabin, within 30 seconds of engine switch pressed |

2 V/DIV., 200 ms./DIV. |

Pulse generation |

OK:

The waveform is similar to that shown in the illustration.

| OK | .gif) |

REPLACE ENGINE SWITCH |

|

|

2. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ENGINE SWITCH) |

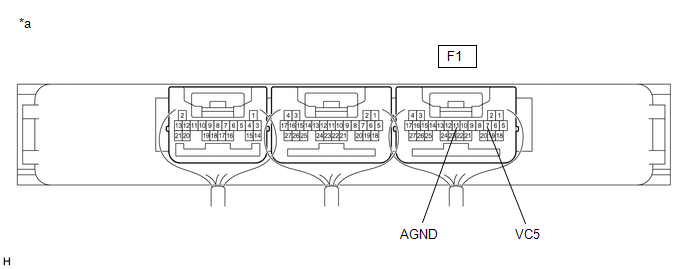

(a) Disconnect the F1 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the F59 engine switch connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F1-7 (VC5) - F59-10 (VC5) |

Always |

Below 1 Ω |

|

F1-11 (AGND) - F59-6 (AGND) |

Always |

Below 1 Ω |

|

F1-7 (VC5) or F59-10 (VC5) - Body ground |

Always |

10 kΩ or higher |

|

F1-11 (AGND) or F59-6 (AGND) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

(a) Reconnect the F1 certification ECU (smart key ECU assembly) connector.

(b) Reconnect the F59 engine switch connector.

(c) Measure the voltage according to the value(s) in the table below.

|

*a |

Component with harness connected (Certification ECU (Smart Key ECU Assembly)) |

- |

- |

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F1-7 (VC5) - F1-11 (AGND) |

Engine switch off, brake pedal not depressed, 30 seconds or more after driver door opened and then closed |

Below 1 V |

| OK | .gif) |

REPLACE ENGINE SWITCH |

| NG | .gif) |

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

ID BOX EEPROM Malfunction (B2790)

ID BOX EEPROM Malfunction (B2790)

DESCRIPTION

When an internal malfunction occurs in the ID code box (immobiliser code ECU),

the certification ECU (smart key ECU assembly) stores this DTC.

DTC No.

Detection I ...

Antenna Coil Open / Short (B2784)

Antenna Coil Open / Short (B2784)

DESCRIPTION

When an open or short circuit is detected in the transponder key amplifier coil

built into the engine switch, the certification ECU (smart key ECU assembly) stores

this DTC. This DTC ...

Other materials:

Toyota CH-R Service Manual > Seat Belt Warning System(w/o Occupant Classification System): Front Passenger Side Seat Belt Warning Light Malfunction

DESCRIPTION

When the ignition switch is ON, the combination meter assembly monitors the state

of the front passenger side seat and the front seat inner belt assembly (front passenger

seat) and also whether the front passenger seat is occupied. If the front passenger

side seat belt is not fast ...

Toyota CH-R Service Manual > Immobiliser System(w/o Smart Key System): Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

Immobiliser System

DTC No.

Detection Item

Link

B2780

Push Switch / Key Unlock Warning Switch Malfunction

B2784

Antenna Coil Open / Short

...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0084

.gif)