Toyota CH-R Service Manual: Inspection

INSPECTION

PROCEDURE

1. INSPECT SPIRAL CABLE SUB-ASSEMBLY

NOTICE:

- Do not remove the steering sensor from the spiral cable sub-assembly when inspecting the spiral cable sub-assembly.

- Remove the steering sensor from the spiral cable sub-assembly only when replacing the spiral cable sub-assembly.

(a) Visually check the spiral cable sub-assembly for defects.

(1) The defects are as follows:

- Scratches

- Small cracks

- Dents

- Chips

- Cracks or other damage to the connector

OK:

No defects are found.

If any of the defects is found, replace the spiral cable sub-assembly with a new one.

(b) Check the spiral cable sub-assembly.

|

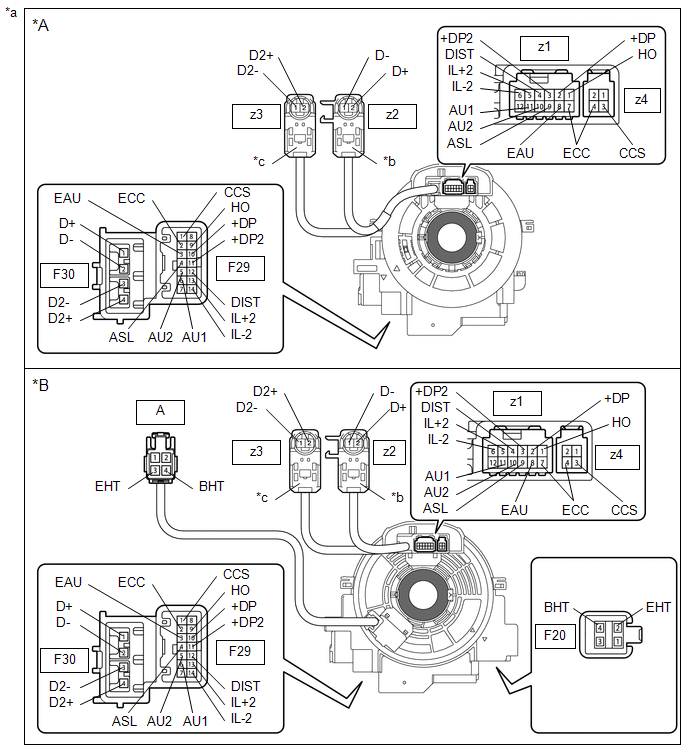

*A |

w/o Steering Heater |

*B |

w/ Steering Heater |

|

*a |

Component without harness connected (Spiral Cable Sub-assembly) |

*b |

Color: Light Green |

|

*c |

Color: Black |

- |

- |

.png) |

Interlock |

- |

- |

NOTICE:

- When rotating the spiral cable sub-assembly, make sure to push on the interlock shown in the illustration to release the interlock mechanism.

- As the spiral cable sub-assembly may break, do not rotate the spiral cable sub-assembly more than the specified amount.

(1) Set the spiral cable sub-assembly to the center position.

- w/o Steering Heater:

Click here

.gif)

- w/ Steering Heater:

Click here

.gif)

(2) Measure the resistance between each terminal of the spiral cable sub-assembly according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F29-1 (CCS) - z4-3 (CCS) |

Always |

3 Ω or less |

|

F29-2 (ECC) - z1-7 (ECC) |

Always |

3 Ω or less |

|

F29-2 (ECC) - z4-4 (ECC) |

Always |

3 Ω or less |

|

F29-3 (EAU) - z1-8 (EAU) |

Always |

3 Ω or less |

|

F29-5 (AU2) - z1-10 (AU2) |

Always |

3 Ω or less |

|

F29-6 (AU1) - z1-11 (AU1) |

Always |

3 Ω or less |

|

F29-9 (HO) - z1-1 (HO) |

Always |

3 Ω or less |

|

F29-10 (+DP) - z1-2 (+DP) |

Always |

3 Ω or less |

|

F29-11 (+DP2) - z1-3 (+DP2) |

Always |

3 Ω or less |

|

F29-12 (DIST) - z1-4 (DIST) |

Always |

3 Ω or less |

|

F29-13 (IL+2) - z1-5 (IL+2) |

Always |

3 Ω or less |

|

F29-14 (IL-2) - z1-6 (IL-2) |

Always |

3 Ω or less |

|

F20-2 (EHT) - z6-3 (EHT)*1 |

Always |

3 Ω or less |

|

F20-4 (BHT) - z6-4 (BHT)*1 |

Always |

3 Ω or less |

|

F30-1 (D+) - z2-2 (D+) |

Always |

Below 1 Ω |

|

F30-2 (D-) - z2-1 (D-) |

Always |

Below 1 Ω |

|

F30-3 (D2-) - z15-1 (D2-)*2 |

Always |

Below 1 Ω |

|

F30-4 (D2+) - z15-2 (D2+)*2 |

Always |

Below 1 Ω |

- *1: w/ Steering Heater

- *2: for Dual Type

(3) After setting the spiral cable sub-assembly to the center position, rotate the spiral cable sub-assembly 2.5 times clockwise, and measure the resistance according to the value(s) in the table below. Then rotate the spiral cable sub-assembly 5 times counterclockwise, and measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F29-1 (CCS) - z4-3 (CCS) |

Always |

3 Ω or less |

|

F29-2 (ECC) - z1-7 (ECC) |

Always |

3 Ω or less |

|

F29-2 (ECC) - z4-4 (ECC) |

Always |

3 Ω or less |

|

F29-3 (EAU) - z1-8 (EAU) |

Always |

3 Ω or less |

|

F29-5 (AU2) - z1-10 (AU2) |

Always |

3 Ω or less |

|

F29-6 (AU1) - z1-11 (AU1) |

Always |

3 Ω or less |

|

F29-9 (HO) - z1-1 (HO) |

Always |

3 Ω or less |

|

F29-10 (+DP) - z1-2 (+DP) |

Always |

3 Ω or less |

|

F29-11 (+DP2) - z1-3 (+DP2) |

Always |

3 Ω or less |

|

F29-12 (DIST) - z1-4 (DIST) |

Always |

3 Ω or less |

|

F29-13 (IL+2) - z1-5 (IL+2) |

Always |

3 Ω or less |

|

F29-14 (IL-2) - z1-6 (IL-2) |

Always |

3 Ω or less |

|

F20-2 (EHT) - A-3 (EHT)*1 |

Always |

3 Ω or less |

|

F20-4 (BHT) - A-4 (BHT)*1 |

Always |

3 Ω or less |

|

F30-1 (D+) - z2-2 (D+) |

Always |

Below 1 Ω |

|

F30-2 (D-) - z2-1 (D-) |

Always |

Below 1 Ω |

|

F30-3 (D2-) - z15-1 (D2-)*2 |

Always |

Below 1 Ω |

|

F30-4 (D2+) - z15-2 (D2+)*2 |

Always |

Below 1 Ω |

- *1: w/ Steering Heater

- *2: for Dual Type

(4) After setting the spiral cable sub-assembly to the center position, rotate the spiral cable sub-assembly 2.5 times clockwise. Then while rotating the spiral cable sub-assembly 5 times counterclockwise, measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F29-1 (CCS) - z4-3 (CCS) |

Always |

3 Ω or less |

|

F29-2 (ECC) - z1-7 (ECC) |

Always |

3 Ω or less |

|

F29-2 (ECC) - z4-4 (ECC) |

Always |

3 Ω or less |

|

F29-3 (EAU) - z1-8 (EAU) |

Always |

3 Ω or less |

|

F29-5 (AU2) - z1-10 (AU2) |

Always |

3 Ω or less |

|

F29-6 (AU1) - z1-11 (AU1) |

Always |

3 Ω or less |

|

F29-9 (HO) - z1-1 (HO) |

Always |

3 Ω or less |

|

F29-10 (+DP) - z1-2 (+DP) |

Always |

3 Ω or less |

|

F29-11 (+DP2) - z1-3 (+DP2) |

Always |

3 Ω or less |

|

F29-12 (DIST) - z1-4 (DIST) |

Always |

3 Ω or less |

|

F29-13 (IL+2) - z1-5 (IL+2) |

Always |

3 Ω or less |

|

F29-14 (IL-2) - z1-6 (IL-2) |

Always |

3 Ω or less |

|

F20-2 (EHT) - A-3 (EHT)*1 |

Always |

3 Ω or less |

|

F20-4 (BHT) - A-4 (BHT)*1 |

Always |

3 Ω or less |

|

F30-1 (D+) - z2-2 (D+) |

Always |

Below 1 Ω |

|

F30-2 (D-) - z2-1 (D-) |

Always |

Below 1 Ω |

|

F30-3 (D2-) - z15-1 (D2-)*2 |

Always |

Below 1 Ω |

|

F30-4 (D2+) - z15-2 (D2+)*2 |

Always |

Below 1 Ω |

- *1: w/ Steering Heater

- *2: for Dual Type

If the result is not as specified, replace the spiral cable sub-assembly.

Components

Components

COMPONENTS

ILLUSTRATION

*1

LOWER STEERING COLUMN COVER SUB-ASSEMBLY

*2

SPIRAL CABLE WITH SENSOR SUB-ASSEMBLY

*3

UPPER STEERI ...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration)

that must be performed after parts are removed, installed, or replaced during th ...

Other materials:

Toyota CH-R Service Manual > Back Door Lock: Components

COMPONENTS

ILLUSTRATION

*A

w/ Package Tray Trim

*B

w/ Tonneau Cover

*1

BACK DOOR LOCK ASSEMBLY

*2

BACK DOOR LOCK COVER

*3

BACK DOOR SIDE GARNISH LH

*4

B ...

Toyota CH-R Service Manual > Windshield Deicer System: Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

NOTICE:

If the battery voltage becomes low, windshield deicer operation is canceled to

prioritize supplying power to the power steering system.

Click here

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected ar ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0073