Toyota CH-R Service Manual: Replacement

REPLACEMENT

CAUTION / NOTICE / HINT

CAUTION:

- Prolonged and repeated contact with engine oil will result in the removal of natural oils from the skin, leading to dryness, irritation and dermatitis. In addition, used engine oil contains potentially harmful contaminants which may cause skin cancer.

- Wear protective clothing and gloves. Avoid contact with used oil. If contact occurs, wash your skin thoroughly with soap or waterless hand cleaner. Never use gasoline, thinners, or solvents to wash the skin.

- In order to protect the environment, dispose of used oil and used oil filters at designated disposal sites only.

PROCEDURE

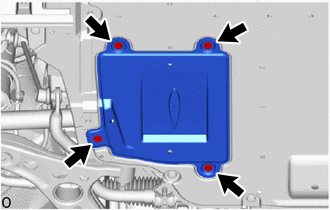

1. REMOVE CENTER NO. 4 ENGINE UNDER COVER

|

(a) Remove the 4 screws and center No. 4 engine under cover. |

|

2. DRAIN ENGINE OIL

(a) Remove the oil filler cap sub-assembly.

(b) Remove the oil pan drain plug and gasket, and drain the engine oil into a container.

(c) Clean the oil pan drain plug.

(d) Install a new gasket to the oil pan drain plug.

(e) Install the oil pan drain plug.

Torque:

37 N·m {377 kgf·cm, 27 ft·lbf}

3. REMOVE OIL FILTER

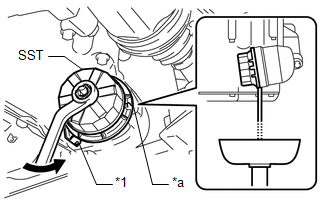

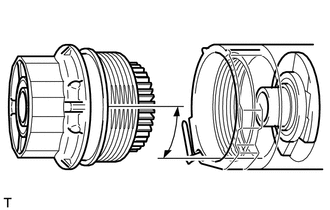

(a) for Oil Filter Sub-assembly Type:

(1) Using SST, remove the oil filter sub-assembly.

SST: 09228-06502

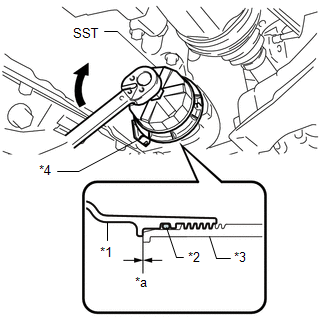

(b) for Oil Filter Element Kit Type:

|

(1) Using SST, loosen the oil filter cap assembly 4 turns, align the cap ribs vertically, and drain the remaining engine oil from the oil filter cap assembly. SST: 09228-06502 NOTICE: Do not remove the oil filter bracket clip when removing the oil filter cap assembly. HINT: Set a container below the oil filter cap assembly before loosening the oil filter cap assembly. |

|

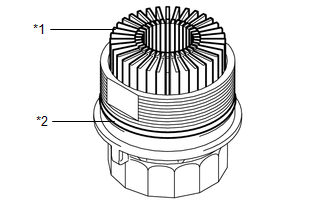

(2) Remove the oil filter cap assembly.

|

(3) Remove the oil filter element and O-ring from the oil filter cap assembly. NOTICE: Do not use any tools to remove the O-ring to prevent damage to the oil filter cap assembly. Be sure to remove it by hand. |

|

4. INSTALL OIL FILTER

(a) for Oil Filter Sub-assembly Type:

(1) Check and clean the oil filter sub-assembly installation surface.

(2) Apply clean engine oil to the gasket of a new oil filter sub-assembly.

(3) Lightly screw the oil filter sub-assembly into place by hand. Tighten it until the gasket contacts the seat.

(4) Using SST, tighten the oil filter sub-assembly.

SST: 09228-06502

- If enough space is available, use a torque wrench to tighten the oil filter sub-assembly.

Torque:

17.5 N·m {178 kgf·cm, 13 ft·lbf}

- If not enough space is available to use a torque wrench, tighten the oil filter sub-assembly 3/4 of a turn by hand or use a common wrench.

(b) for Oil Filter Element Kit Type:

(1) Clean the inside of the oil filter cap assembly, the threads and O-ring groove.

|

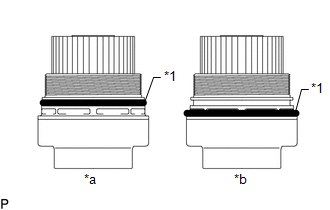

(2) Apply a small amount of engine oil to a new O-ring and install it to the oil filter cap assembly. NOTICE:

|

|

(3) Set a new oil filter element in the oil filter cap assembly.

(4) Remove any dirt or foreign matter from the installation surface of the engine.

|

(5) Apply a small amount of engine oil to the O-ring of the oil filter cap assembly again. Align the cutout in the oil filter cap assembly threads 90° to the grooves in the oil filter bracket and temporarily tighten the oil filter cap assembly. NOTICE: Make sure that the O-ring does not get caught between the parts. |

|

|

(6) Using SST, tighten the oil filter cap assembly. SST: 09228-06502 Torque: 25 N·m {255 kgf·cm, 18 ft·lbf} NOTICE:

|

|

5. ADD ENGINE OIL

(a) Add new engine oil and install the oil filler cap sub-assembly.

Standard Oil Grade: (w/o Canister Pump Module):|

Oil Grade |

Oil Viscosity (SAE) |

|---|---|

|

API grade SL "Energy-Conserving", SM "Energy-Conserving", SN "Resource-Conserving" or ILSAC multigrade engine oil |

|

|

API grade SL, SM or SN multigrade engine oil |

|

|

Oil Grade |

Oil Viscosity (SAE) |

|---|---|

|

ILSAC GF-5 multigrade engine oil |

|

|

Item |

Standard Condition |

|---|---|

|

Drain and refill with oil filter change |

4.2 liters (4.4 US qts, 3.7 Imp. qts) |

|

Drain and refill without oil filter change |

3.9 liters (4.1 US qts, 3.4 Imp. qts) |

|

Dry fill |

4.7 liters (5.0 US qts, 4.1 Imp. qts) |

6. INSPECT FOR OIL LEAK

(a) Start the engine. Make sure that there are no engine oil leaks from the area that was worked on.

7. CHECK ENGINE OIL LEVEL

Click here

.gif)

8. INSTALL CENTER NO. 4 ENGINE UNDER COVER

(a) Install the center No. 4 engine under cover with the 4 screws.

Components

Components

COMPONENTS

ILLUSTRATION

*A

for Oil Filter Sub-assembly Type

*B

for Oil Filter Element Kit Type

*1

CENTER NO. 4 ENGINE UNDER ...

3zr-fae Spark Plug

3zr-fae Spark Plug

Components

COMPONENTS

ILLUSTRATION

*1

IGNITION COIL ASSEMBLY

*2

NO. 2 CYLINDER HEAD COVER

*3

SPARK PLUG

-

...

Other materials:

Toyota CH-R Service Manual > Transmission Control Cable: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration)

that must be performed after parts are removed, installed, or replaced during the

transmission control cable assembly removal/installation are shown below.

Necessary Procedure A ...

Toyota CH-R Service Manual > Theft Deterrent System: Customize Parameters

CUSTOMIZE PARAMETERS

CUSTOMIZE THEFT DETERRENT SYSTEM

NOTICE:

When the customer requests a change in a function, first make sure that

the function can be customized.

Be sure to make a note of the current settings before customizing.

When troubleshooting a function, first ma ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0081