Toyota CH-R Service Manual: Components

COMPONENTS

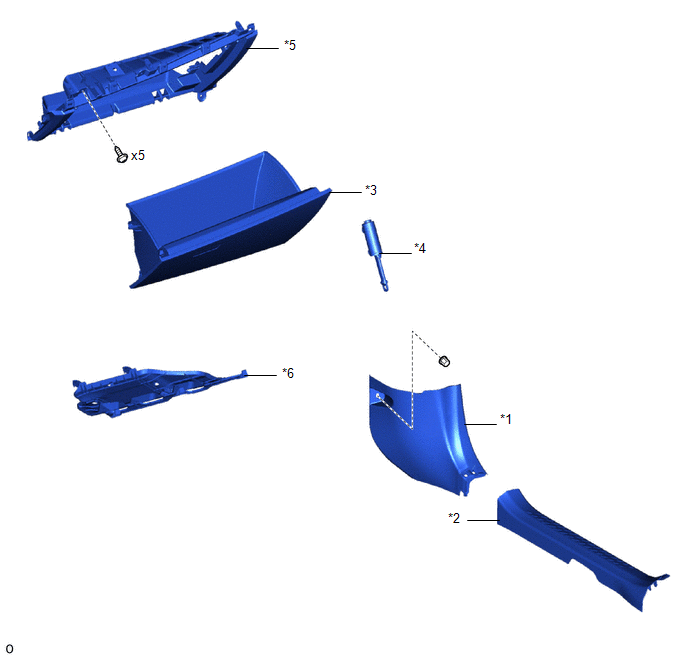

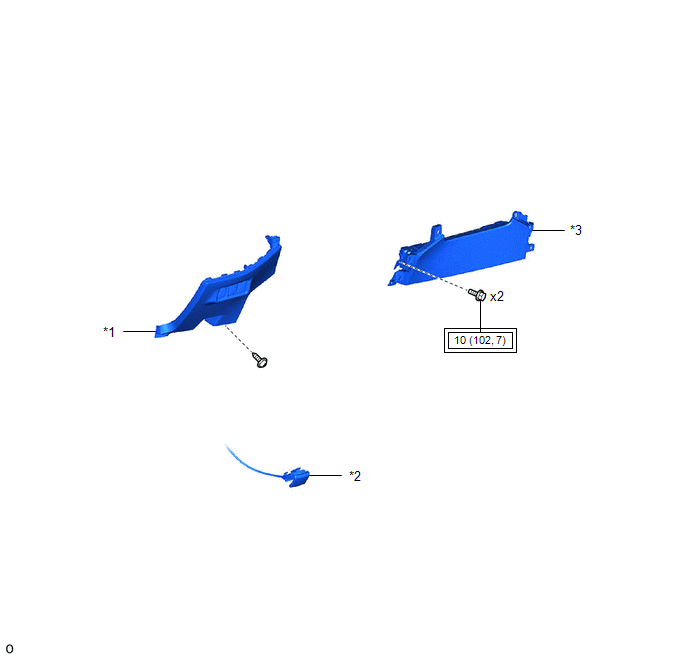

ILLUSTRATION

|

*1 |

COWL SIDE TRIM BOARD RH |

*2 |

FRONT DOOR SCUFF PLATE RH |

|

*3 |

GLOVE COMPARTMENT DOOR ASSEMBLY |

*4 |

GLOVE COMPARTMENT DOOR STOPPER SUB-ASSEMBLY |

|

*5 |

NO. 2 INSTRUMENT PANEL LOWER FINISH PANEL |

*6 |

NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY |

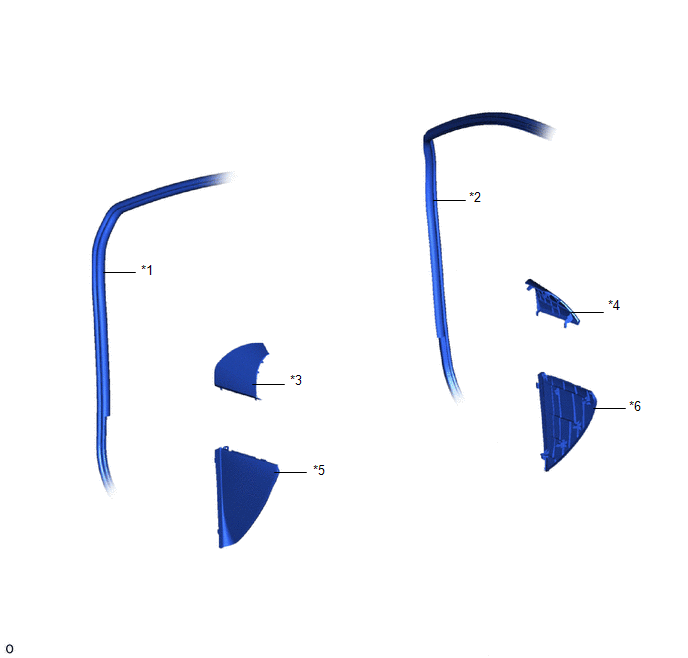

ILLUSTRATION

|

*1 |

FRONT DOOR OPENING TRIM WEATHERSTRIP LH |

*2 |

FRONT DOOR OPENING TRIM WEATHERSTRIP RH |

|

*3 |

INSTRUMENT PANEL FINISH END PANEL LH |

*4 |

INSTRUMENT PANEL FINISH END PANEL RH |

|

*5 |

INSTRUMENT SIDE PANEL LH |

*6 |

INSTRUMENT SIDE PANEL RH |

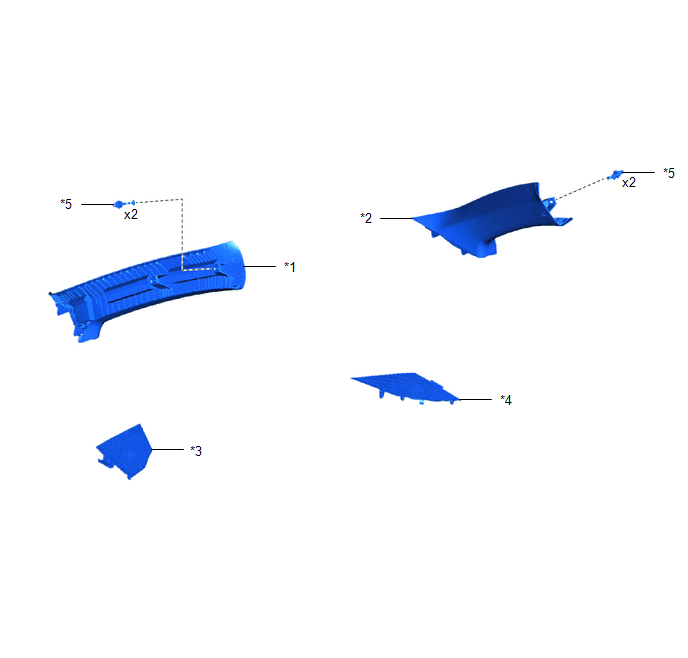

ILLUSTRATION

|

*1 |

FRONT PILLAR GARNISH LH |

*2 |

FRONT PILLAR GARNISH RH |

|

*3 |

NO. 1 INSTRUMENT PANEL SPEAKER PANEL SUB-ASSEMBLY |

*4 |

NO. 2 INSTRUMENT PANEL SPEAKER PANEL SUB-ASSEMBLY |

|

*5 |

FRONT PILLAR GARNISH CLIP |

- |

- |

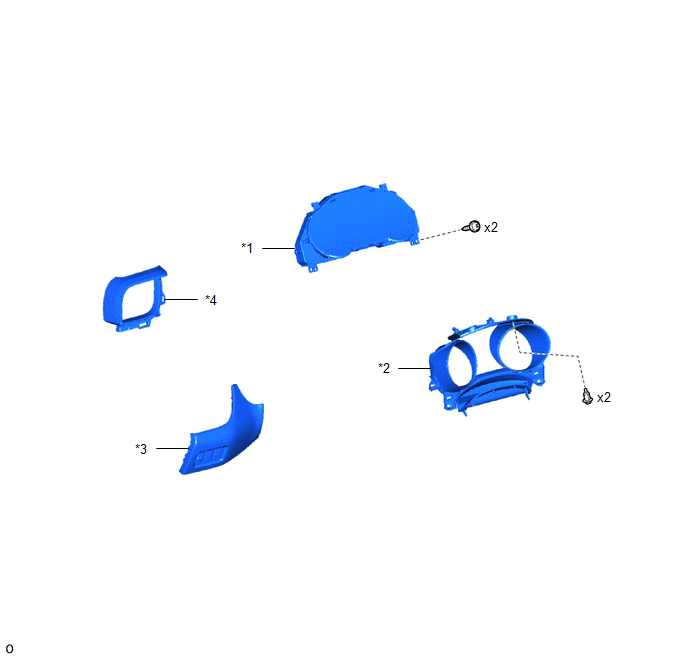

ILLUSTRATION

|

*1 |

COMBINATION METER ASSEMBLY |

*2 |

INSTRUMENT CLUSTER FINISH PANEL ASSEMBLY |

|

*3 |

INSTRUMENT CLUSTER FINISH PANEL SUB-ASSEMBLY |

*4 |

NO. 2 INSTRUMENT PANEL GARNISH SUB-ASSEMBLY |

ILLUSTRATION

|

*1 |

FUSE BOX OPENING COVER |

*2 |

HOOD LOCK CONTROL LEVER SUB-ASSEMBLY |

|

*3 |

LOWER NO. 1 INSTRUMENT PANEL AIRBAG ASSEMBLY WITH DOOR |

- |

- |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

- |

- |

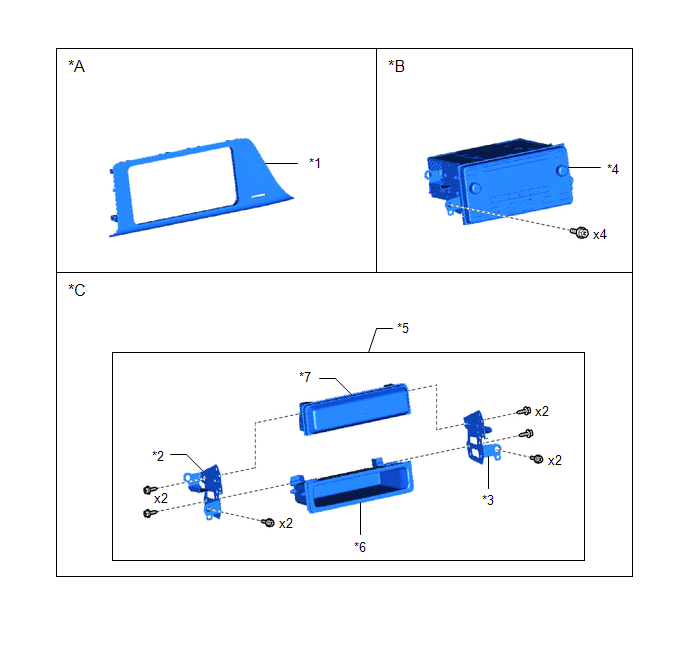

ILLUSTRATION

|

*A |

w/o Display |

*B |

w/ Radio Receiver |

|

*C |

w/o Radio Receiver |

- |

- |

|

*1 |

INSTRUMENT CLUSTER FINISH PANEL SUB-ASSEMBLY |

*2 |

NO. 1 RADIO BRACKET |

|

*3 |

NO. 2 RADIO BRACKET |

*4 |

RADIO RECEIVER ASSEMBLY WITH BRACKET |

|

*5 |

STEREO OPENING COVER WITH BRACKET |

*6 |

NO. 2 STEREO OPENING COVER |

|

*7 |

STEREO OPENING COVER |

- |

- |

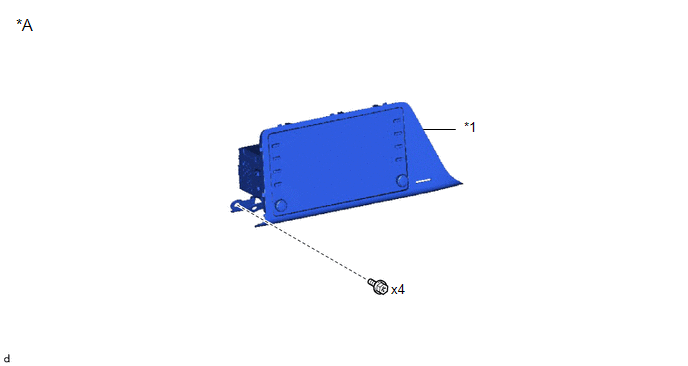

ILLUSTRATION

|

*A |

for Radio and Display Type |

- |

- |

|

*1 |

RADIO AND DISPLAY RECEIVER ASSEMBLY WITH BRACKET |

- |

- |

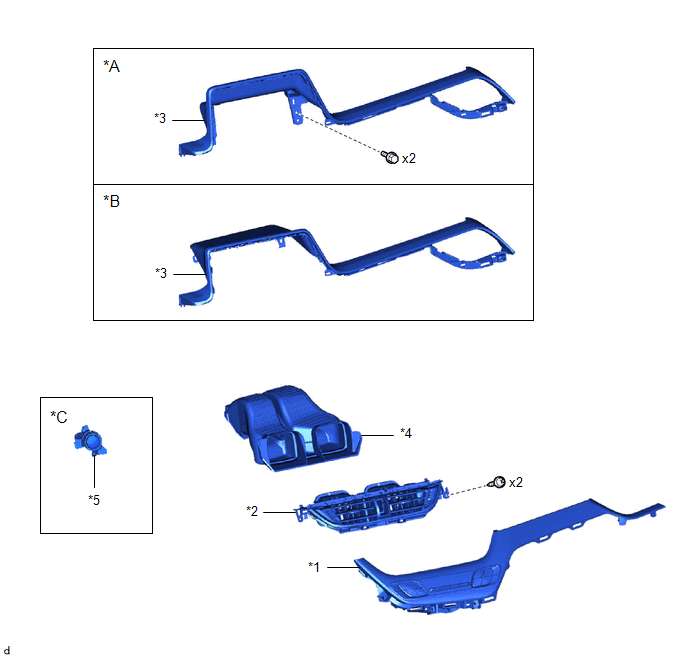

ILLUSTRATION

|

*A |

w/ Display |

*B |

w/o Display |

|

*C |

w/ Smart Key System |

- |

- |

|

*1 |

INSTRUMENT CLUSTER FINISH LOWER CENTER PANEL SUB-ASSEMBLY |

*2 |

INSTRUMENT PANEL CENTER REGISTER ASSEMBLY |

|

*3 |

NO. 1 INSTRUMENT PANEL GARNISH SUB-ASSEMBLY |

*4 |

NO. 2 HEATER TO REGISTER DUCT SUB-ASSEMBLY |

|

*5 |

STARTER SWITCH BEZEL |

- |

- |

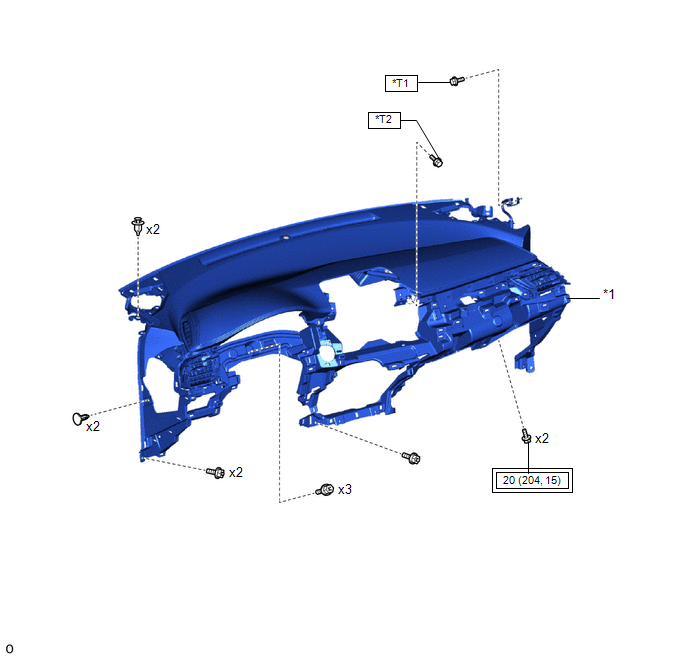

ILLUSTRATION

|

*1 |

INSTRUMENT PANEL SAFETY PAD SUB-ASSEMBLY |

- |

- |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

*T1 |

for TMMT Made, Type A: 10.5 N*m (107 kgf*cm, 8 ft.*lbf) for TMMT Made, Type B: 10 N*m (102 kgf*cm, 7 ft.*lbf) for TMC Made: 10 N*m (102 kgf*cm, 7 ft.*lbf) |

*T2 |

for TMMT Made, Type A: 8.3 N*m (85 kgf*cm, 73 in.*lbf) for TMMT Made, Type B: 10 N*m (102 kgf*cm, 7 ft.*lbf) for TMC Made: 10 N*m (102 kgf*cm, 7 ft.*lbf) |

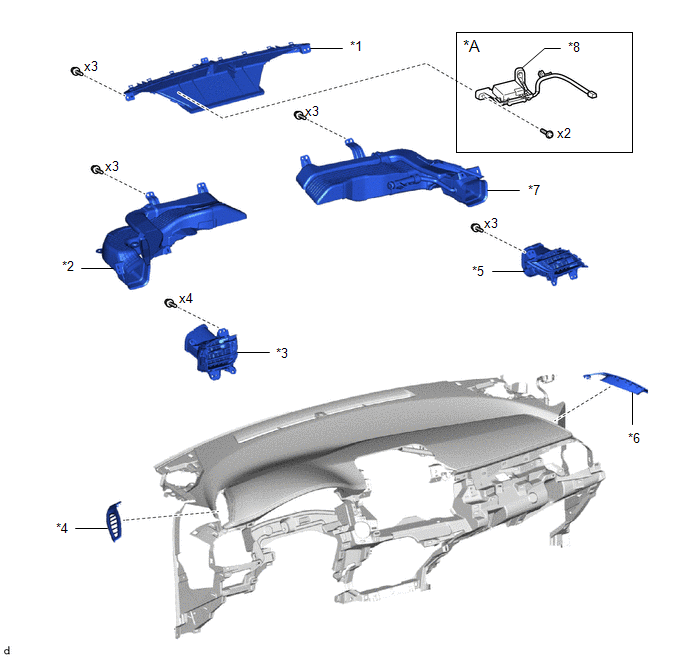

ILLUSTRATION

|

*A |

for Radio and Display Type |

- |

- |

|

*1 |

DEFROSTER NOZZLE ASSEMBLY |

*2 |

NO. 1 HEATER TO REGISTER DUCT SUB-ASSEMBLY |

|

*3 |

NO. 1 INSTRUMENT PANEL REGISTER ASSEMBLY |

*4 |

NO. 1 SIDE DEFROSTER NOZZLE |

|

*5 |

NO. 2 INSTRUMENT PANEL REGISTER ASSEMBLY |

*6 |

NO. 2 SIDE DEFROSTER NOZZLE |

|

*7 |

NO. 3 HEATER TO REGISTER DUCT SUB-ASSEMBLY |

*8 |

TELEPHONE AND GPS ANTENNA ASSEMBLY |

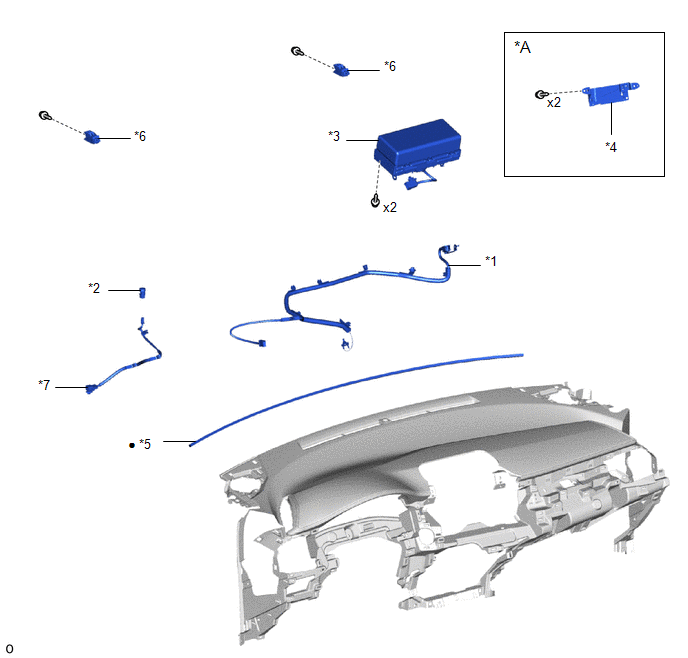

ILLUSTRATION

|

*A |

w/ Ion Generator |

- |

- |

|

*1 |

ANTENNA CORD SUB-ASSEMBLY |

*2 |

AUTOMATIC LIGHT CONTROL SENSOR |

|

*3 |

INSTRUMENT PANEL PASSENGER AIRBAG ASSEMBLY |

*4 |

ION GENERATOR SUB-ASSEMBLY |

|

*5 |

NO. 1 INSTRUMENT PANEL CUSHION |

*6 |

NO. 1 INSTRUMENT PANEL PIN |

|

*7 |

NO. 2 INSTRUMENT PANEL WIRE |

- |

- |

|

● |

Non-reusable part |

- |

- |

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration)

that must be performed after parts are removed, installed, or replaced during th ...

Other materials:

Toyota CH-R Service Manual > Air Conditioning Unit(for Denso Made): Components

COMPONENTS

ILLUSTRATION

*1

COWL BODY MOUNTING REINFORCEMENT LH

*2

COWL BODY MOUNTING REINFORCEMENT RH

*3

NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

*4

OUTER COWL TOP PANEL SUB-ASSEMBLY

*5 ...

Toyota CH-R Service Manual > Outer Rear View Mirror Glass: Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

PROCEDURE

1. REMOVE OUTER MIRROR

(a) Apply protective tape to the area as shown in the illustration.

Protective Tape

...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0091