Toyota CH-R Service Manual: Replacement

REPLACEMENT

PROCEDURE

1. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

(a) Start the engine.

(b) Operate the compressor under the conditions shown below:

|

Item |

Condition |

|---|---|

|

Operating time |

3 minutes or more |

|

Temperature setting |

Max cool |

|

Blower speed |

High |

|

Engine |

Idling |

|

A/C switch |

On |

This causes most of the compressor oil from the various components of the A/C system to collect in the compressor.

HINT:

It is not necessary to operate the compressor if the A/C does not operate because of compressor lock, etc.

(c) Stop the engine.

(d) Recover the refrigerant from the A/C system using a refrigerant recovery unit.

HINT:

Use the refrigerant recovery unit in accordance with the manufacturer's instruction manual.

2. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT

(a) Perform vacuum purging using a vacuum pump or appropriate equipment.

(b) Charge the air conditioning system with refrigerant.

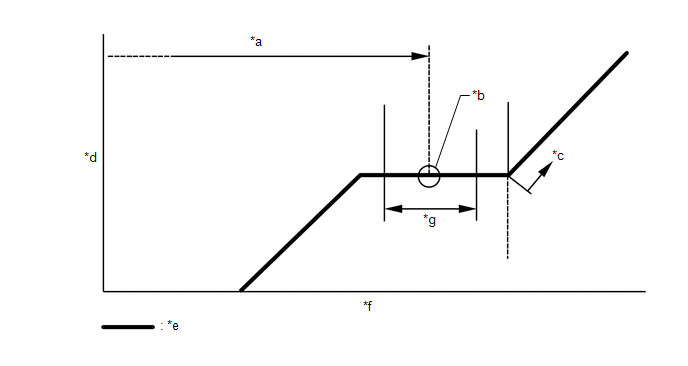

Refrigerant Type:

HFC-134a (R134a)

|

*a |

Standard Charge Amount |

*b |

Mean Value in Proper Range |

|

*c |

Overcharged |

*d |

High Pressure |

|

*e |

Sub-cool System |

*f |

Refrigerant Amount |

|

*g |

+/-30 g (+/-1.05 oz) |

- |

- |

Standard Charge Amount:

380 to 440 g (13.4 to 15.5 oz)

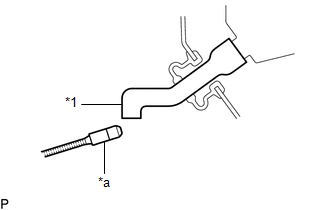

SST: 09985-20010

09985-02010

09985-02050

09985-02060

09985-02070

09985-02080

09985-02090

09985-02110

09985-02130

09985-02140

09985-02150

NOTICE:

- Do not turn the A/C switch on before charging the air conditioning system with refrigerant. Doing so may cause the compressor to work without refrigerant, resulting in overheating of the compressor.

- The refrigerant amount should be checked by quantity (weight).

- The graph above is shown for reference only.

HINT:

Ensure that sufficient refrigerant is available to recharge the system when using a refrigerant recovery unit. Refrigerant recovery units are not always able to recover 100% of the refrigerant from an air conditioning system.

3. WARM UP ENGINE

(a) Keep the A/C switch on for at least 2 minutes to warm up the compressor.

NOTICE:

To prevent damage to the compressor, be sure to warm up the compressor when turning the air conditioning on after removing and installing any air conditioning system lines (including the compressor).

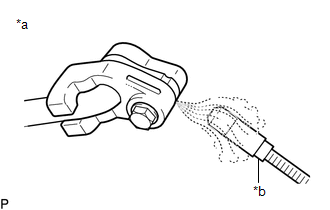

4. INSPECT FOR REFRIGERANT LEAK

(a) After recharging the air conditioning system with refrigerant, inspect for refrigerant leaks using a halogen leak detector.

(b) Carry out the test under the following conditions:

- Turn the ignition switch off.

- Ensure good ventilation (the halogen leak detector may react to volatile gases which are not refrigerant, such as gasoline vapor and exhaust gas).

- Repeat the inspection 2 or 3 times.

- Measure the pressure to make sure that there is some refrigerant remaining

in the air conditioning system.

Pressure when the compressor is off: approximately 392 to 588 kPa (3.9 to 5.9 kgf/cm2, 57 to 85 psi)

|

(c) Using a halogen leak detector, inspect for refrigerant leaks from the air conditioning system. |

|

|

(d) Bring the halogen leak detector close to the drain cooler hose with the detector power off, and then turn the detector on. HINT:

|

|

(e) If a refrigerant leak is not detected from the drain cooler hose, remove the blower motor control from the cooling unit. Insert the halogen leak detector sensor into the unit and check for leaks.

(f) Disconnect the pressure sensor connector and leave it for approximately 20 minutes. Bring the halogen leak detector close to the pressure sensor and check for leaks.

HINT:

When checking for leaks, the presence of oily dirt at a joint can indicate a leak.

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT REFRIGERANT PRESSURE WITH MANIFOLD GAUGE SET

HINT:

The following examples show the readings of a manifold gauge set and the corresponding

air condition ...

Other materials:

Toyota CH-R Service Manual > Steering Lock System: IG2 Signal Malfunction (B2788)

DESCRIPTION

This DTC is stored when the steering lock ECU (steering lock actuator or upper

bracket assembly) detects an IG2 power supply malfunction.

HINT:

The steering lock ECU (steering lock actuator or upper bracket assembly) is not

connected to the CAN communication system. However, the s ...

Toyota CH-R Service Manual > Blower Unit(for Denso Made): Installation

INSTALLATION

PROCEDURE

1. INSTALL BLOWER ASSEMBLY

(a) Engage the guides to install the air conditioning radiator assembly.

(b) Install the 2 screws.

(c) Engage the guides.

(d) ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0152