Toyota CH-R Service Manual: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during the air conditioner unit assembly removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced|

Replacement Part or Procedure |

Necessary Procedures |

Effects / Inoperative when not performed |

Link |

|---|---|---|---|

|

Disconnect cable from negative battery terminal |

Memorize steering angle neutral point |

Lane departure alert system (w/ Steering Control) |

|

|

Pre-collision system |

|||

|

Initialize back door lock |

Power door lock control system |

|

|

|

Initialize servo motor (Air conditioning system) |

DTCs are stored |

|

PROCEDURE

1. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM (for HFC-134a(R134a))

Click here

.gif)

2. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM (for HFO-1234yf(R1234yf))

Click here

.gif)

3. DRAIN ENGINE COOLANT

Click here

.gif)

4. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

Click here

.gif)

5. REMOVE NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

Click here

.gif)

6. REMOVE WATER GUARD PLATE LH

Click here

.gif)

7. REMOVE COWL BODY MOUNTING REINFORCEMENT LH

Click here

.gif)

8. REMOVE COWL BODY MOUNTING REINFORCEMENT RH

Click here

.gif)

9. REMOVE OUTER COWL TOP PANEL SUB-ASSEMBLY

Click here

.gif)

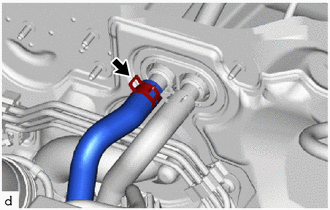

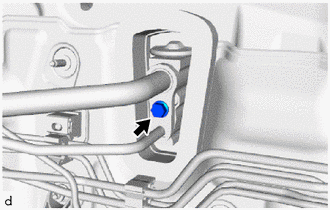

10. DISCONNECT OUTLET HEATER WATER HOSE

|

(a) Slide the hose clip to disconnect the outlet heater water hose. NOTICE:

|

|

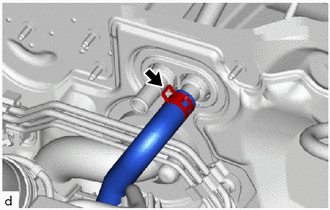

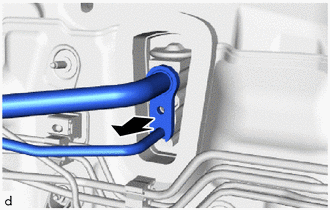

11. DISCONNECT INLET HEATER WATER HOSE

|

(a) Slide the hose clip to disconnect the inlet heater water hose. NOTICE:

|

|

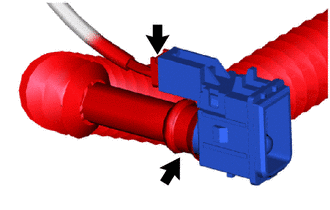

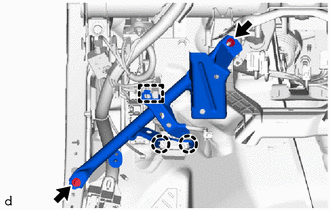

12. DISCONNECT SUCTION PIPE SUB-ASSEMBLY

|

(a) Remove the bolt. |

|

|

(b) Disconnect the suction pipe sub-assembly and cooler refrigerant liquid pipe A shown in the illustration. |

|

(c) Remove the 2 O-rings from the suction pipe sub-assembly and cooler refrigerant liquid pipe A.

NOTICE:

Seal the openings of the disconnected parts using vinyl tape to prevent entry of moisture and foreign matter.

13. REMOVE FRONT SEAT ASSEMBLY LH

Click here

.gif)

14. REMOVE FRONT SEAT ASSEMBLY RH

HINT:

Use the same procedure as for the LH side.

15. REMOVE INSTRUMENT PANEL SAFETY PAD SUB-ASSEMBLY

Click here

.gif)

16. REMOVE STEERING COLUMN ASSEMBLY

Click here

.gif)

17. REMOVE WINDSHIELD WIPER RELAY ASSEMBLY

Click here

.gif)

18. REMOVE ECU INTEGRATION BOX RH

Click here

.gif)

19. REMOVE COOLER THERMISTOR (ROOM TEMPERATURE SENSOR)

|

(a) Disconnect the connector and aspirator to remove the cooler thermistor (room temperature sensor). |

|

20. REMOVE NO. 3 DASH PANEL INSULATOR PAD

|

(a) Disengage the clips to remove the No. 3 dash panel insulator pad. |

|

|

(b) Remove the 2 front floor carpet clips. |

|

(c) Remove the clip.

.png) |

Remove in this Direction |

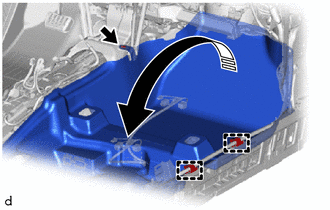

(d) Disengage the clamps to turn back the front floor carpet assembly as shown in the illustration.

21. REMOVE REAR NO. 6 AIR DUCT (w/ Rear Air Duct)

(a) Disengage the claws to remove the rear No. 6 air duct as shown in the illustration.

.png)

.png) |

Remove in this Direction |

22. REMOVE REAR NO. 5 AIR DUCT (w/ Rear Air Duct)

.png)

.png) |

Remove in this Direction |

(a) Disengage the claws to remove the rear No. 5 air duct as shown in the illustration.

23. REMOVE REAR NO. 4 AIR DUCT (w/ Rear Air Duct)

|

(a) Remove the 2 front floor carpet clips. |

|

(b) Remove the clip.

.png)

.png) |

Remove in this Direction |

(c) Disengage the clamps to turn back the front floor carpet assembly as shown in the illustration.

(d) Disengage the claws to remove the rear No. 4 air duct as shown in the illustration.

.png)

.png) |

Remove in this Direction |

24. REMOVE REAR NO. 3 AIR DUCT (w/ Rear Air Duct)

(a) Disengage the claws to remove the rear No. 3 air duct as shown in the illustration.

.png)

.png) |

Remove in this Direction |

25. REMOVE REAR NO. 2 AIR DUCT (w/ Rear Air Duct)

.png)

.png) |

Remove in this Direction |

(a) Disengage the claws to remove the rear No. 2 air duct.

26. REMOVE REAR NO. 1 AIR DUCT (w/ Rear Air Duct)

(a) Disengage the claws to remove the rear No. 1 air duct as shown in the illustration.

.png) |

Remove in this Direction |

27. DISCONNECT NO. 1 INSTRUMENT PANEL BRACE SUB-ASSEMBLY

(a) w/ PTC Heater:

|

(1) Remove the bolt to disconnect the ground wire. |

|

|

(b) Remove the 2 nuts and separate the relay block assembly. |

|

|

(c) Disengage the clamps to disconnect the wire harness. |

|

|

(d) Remove the bolt, screw, nut and No.1 instrument panel brace sub-assembly. |

|

28. REMOVE NO. 2 INSTRUMENT PANEL BRACE SUB-ASSEMBLY

|

(a) Remove the bolt to disconnect the ground wire. |

|

(b) Disengage the clamps to disconnect the wire harness.

(c) Remove the bolt, screw, nut and No. 2 instrument panel brace sub-assembly.

29. REMOVE NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY (for Cold Area Specification Vehicles)

|

(a) Disengage the clamp and claws. |

|

(b) Remove the bolt, nut and No. 3 instrument panel to cowl brace sub-assembly.

30. REMOVE NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY (except Cold Area Specification Vehicles)

|

(a) Disengage the clamp and claws. |

|

(b) Remove the bolt, nut and No. 3 instrument panel to cowl brace sub-assembly.

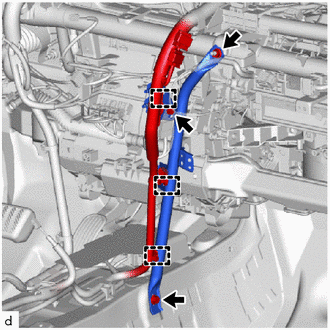

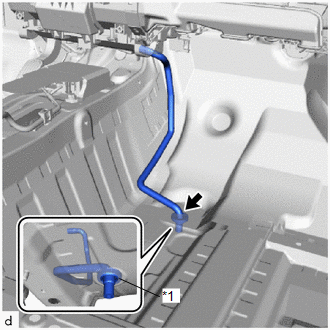

31. SEPARATE DRAIN COOLER HOSE

|

(a) Disconnect the drain cooler hose. NOTICE: If the cooler unit drain hose grommet is disconnected from the vehicle body while disconnecting the drain cooler hose, make sure to replace it with a new one. Failure to do so may cause water ingress. |

|

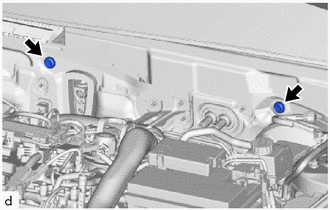

32. DISCONNECT INSTRUMENT PANEL WIRE

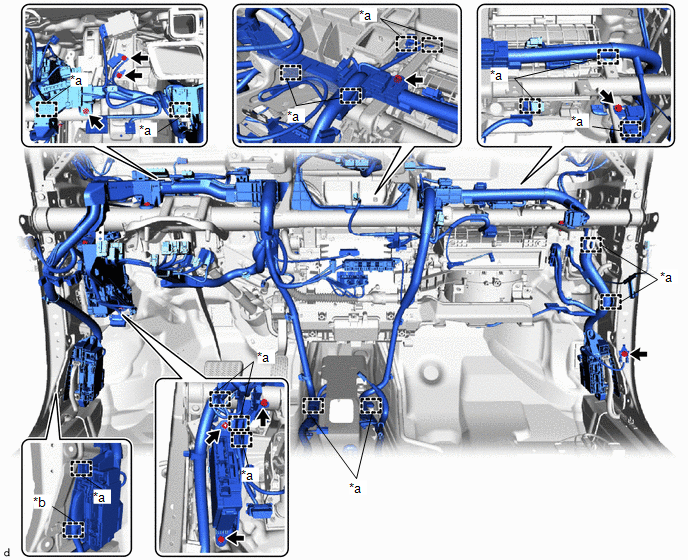

(a) Disconnect each connector.

|

*a |

Clamp |

*b |

Hook |

(b) Remove the bolt and screw.

(c) Remove the 4 bolts to disconnect the 4 ground wires.

(d) Remove the bolt and nut to separate the instrument panel junction block assembly with main body ECU.

(e) Disengage clamps and hook to disconnect the instrument panel wire.

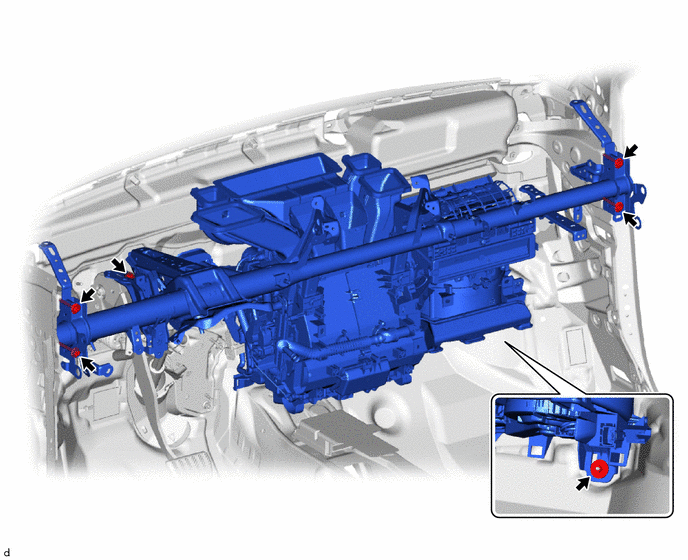

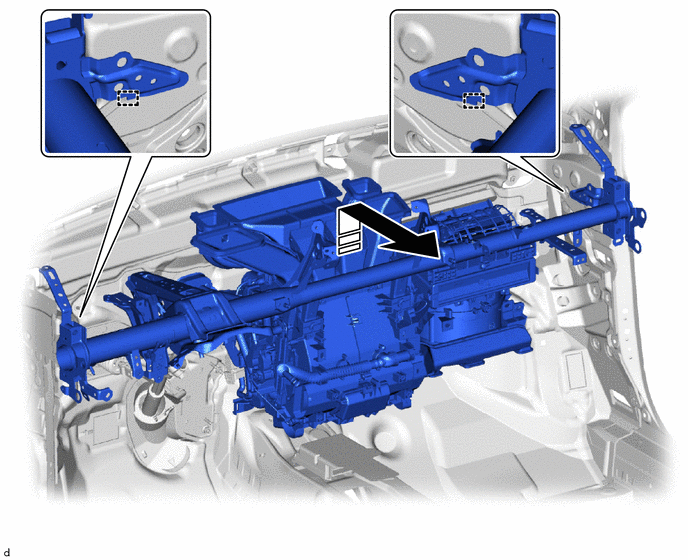

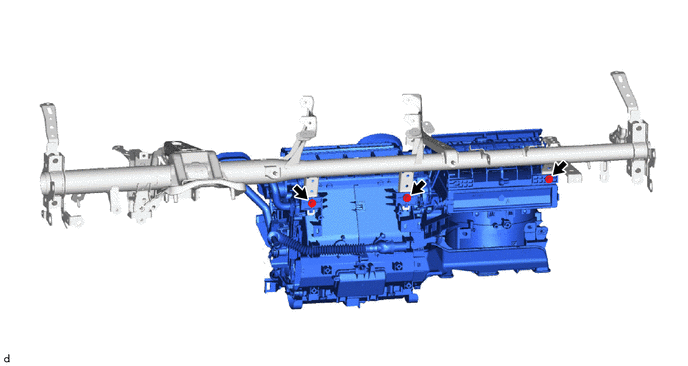

33. REMOVE INSTRUMENT PANEL REINFORCEMENT ASSEMBLY WITH AIR CONDITIONER UNIT ASSEMBLY

NOTICE:

- Be sure to support the air conditioner unit assembly when removing it. Failure to do so may cause the bracket of the air conditioner unit assembly to break.

- When disassembling the air conditioner unit assembly, eliminate static electricity by touching the vehicle body to prevent the components from being damaged.

|

(a) Remove the 2 bolts. |

|

(b) Remove the 5 bolts.

(c) Remove the nut.

|

(d) Disengage the clamps. |

|

(e) Disconnect 2 connectors.

(f) Disengage the guides to remove the instrument panel reinforcement assembly with air conditioner unit assembly as shown in the illustration.

.png) |

Remove in this Direction |

- |

- |

34. REMOVE AIR CONDITIONER UNIT ASSEMBLY

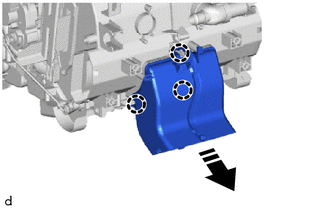

(a) Remove the 3 bolts and air conditioner unit assembly from the instrument panel reinforcement assembly.

35. REMOVE LOWER DEFROSTER NOZZLE ASSEMBLY

|

(a) Disengage the claws to remove the lower defroster nozzle assembly. |

|

Components

Components

COMPONENTS

ILLUSTRATION

*1

COWL BODY MOUNTING REINFORCEMENT LH

*2

COWL BODY MOUNTING REINFORCEMENT RH

*3

NO. 1 HEATER AIR DU ...

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. PRECAUTION

NOTICE:

Make sure to perform initialization after replacing the air conditioning radiator

damper servo sub-assembly. If initialization is not performed, the a ...

Other materials:

Toyota CH-R Service Manual > How To Troubleshoot Ecu Controlled Systems: General Information

GENERAL INFORMATION

A large number of ECU controlled systems are used in this vehicle. In

general, ECU controlled systems are considered to be very intricate, requiring

a high level of technical knowledge to troubleshoot. However, most problem

checking procedures only involve ins ...

Toyota CH-R Service Manual > Instrument Panel Safety Pad: Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL NO. 1 INSTRUMENT PANEL CUSHION

(a) Install a new instrument panel cushion as shown in the illustration.

Standard Measurement:

Area

Measurement

A

3.0 mm (0.118 in.)

...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0093

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)