Toyota CH-R Service Manual: Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

1. REPAIR INSTRUCTION

(a) Clean the vehicle body surface.

(1) Using a heat light, heat the vehicle body surface.

Heating Temperature|

Item |

Temperature |

|---|---|

|

Vehicle Body |

40 to 60°C (104 to 140°F) |

CAUTION:

- Do not touch the heat light and heated parts, touching the heat light may result in burns.

- Touching heated parts for a long time may result in burns.

.png)

|

*a |

Heated Part |

|

*b |

Heat Light |

NOTICE:

Do not heat the vehicle body excessively.

(2) Wipe off any tape adhesive residue with cleaner.

(b) Installation temperature

(1) When the ambient temperature is below 15°C (59°F), perform the installation procedure after warming the vehicle body surface (installation surface of the door frame) and tape up to between 20 and 30°C (68 and 86°F) using a heat light. When the ambient temperature is above 35°C (95°F), cool the vehicle body surface (installation surface of the door frame) and tape down to between 20 and 30°C (68 and 86°F) prior to installation.

HINT:

- The most appropriate temperature for installing the tape is 25°C (77°F).

- When the temperature is low, the tape becomes stiff and comes off easily. When the temperature is high, the tape elasticity increases.

(c) Before installation

(1) Remove any coating roughness or dirt on and around the vehicle body surface where the tape will be installed (installation surface of the door frame). If any roughness or dirt remains when pressing the tape onto the surface, air will be trapped under the tape and result in a poor appearance.

HINT:

Spray water on the shop floor to settle any dust.

(d) Key points for handling the tape

(1) The tape bends and rolls up easily. Store the tape between flat pieces of cardboard or other similar objects and keep it dry and flat.

NOTICE:

Do not bend the tape or leave it in high temperature places.

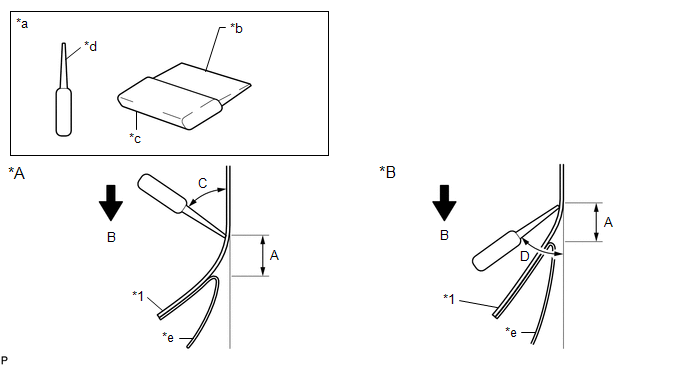

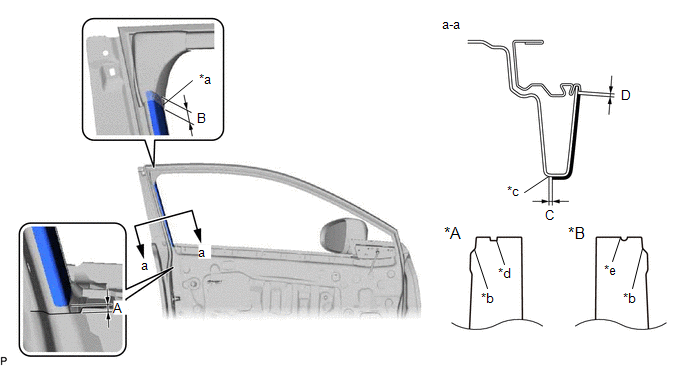

(e) Key points for installation of the tape (How to use a squeegee and installation procedure for flat surfaces)

NOTICE:

- Position the tape accurately to achieve a neat finish and to avoid peeling.

- The tape cannot be reused because it deforms after removal.

(1) To avoid air bubbles, slightly raise the part of the tape that is going to be applied so that its adhesive surface does not touch the vehicle body prematurely. Tilt the squeegee at 40 to 50° (pressing forward) or 30 to 45° (pulling) to the vehicle body surface and press the tape onto the vehicle body surface with a force of 20 to 30 N (2 to 3 kgf, 4.5 to 6.7 lbf) at a constant slow speed of 30 to 70 mm (1.18 to 2.76 in.) per second.

|

*A |

Pressing Forward |

*B |

Pulling |

|

*1 |

Black Out Tape |

- |

- |

|

*a |

Side View |

*b |

Non-padded Side |

|

*c |

Padded Side |

*d |

Squeegee |

|

*e |

Release Paper |

- |

- |

Standard Measurement:

|

Area |

Measurement |

Area |

Measurement |

|---|---|---|---|

|

A |

10 to 20 mm (0.394 to 0.787 in.) |

B |

30 to 70 mm/sec. (1.18 to 2.76 in./sec.) |

|

C |

40 to 50° (for pressing forward) |

D |

30 to 45° (for pulling) |

NOTICE:

Be sure to observe the specified pressing speed, force and angle of the squeegee to avoid wrinkles or air bubbles.

HINT:

- Either angle of the squeegee (pressing forward or pulling) is acceptable.

- Be sure to apply the tape while removing the release paper 10 to 20 mm (0.394 to 0.787 in.) from the edge of the squeegee.

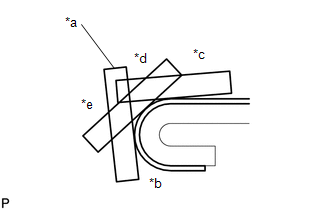

(f) Key points for installation of the tape (How to use a squeegee and installation procedure for hemmed surfaces)

|

(1) If it is difficult to apply the tape, install it in several steps as shown in the illustration. Use your fingers or the padded surface of a squeegee to slowly apply the tape to the hem of the vehicle, especially for a small hem. HINT: When applying tape to the backside of a hem, remove the release paper and use your fingers or the padded surface of a squeegee. |

|

(g) Key points for installation of the tape (How to use a squeegee and installation procedure for corners)

(1) Remove the release paper and apply the tape carefully with your fingers.

(2) Before applying the tape to each corner, heat the tape using a heat light and gradually apply it, avoiding wrinkles on the tape to achieve a neat finish.

(h) Check after installation

(1) After completing the installation, check if the tape is installed neatly. If the tape is not installed neatly, install a new tape.

NOTICE:

Do not reuse the tape.

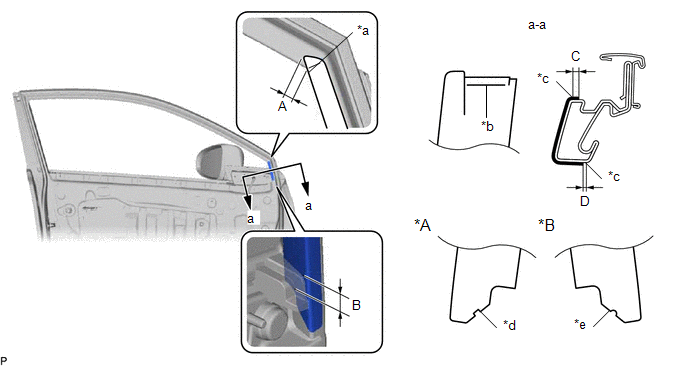

2. INSTALL NO. 2 FRONT DOOR STRIPE

(a) Refer to the illustration to position a new No. 2 front door stripe.

|

*A |

LH Side |

*B |

RH Side |

|

*a |

Point A |

*b |

Point B |

|

*c |

Edge of Curved Surface |

*d |

Square |

|

*e |

Round |

- |

- |

Standard Measurement:

|

Area |

Measurement |

Area |

Measurement |

|---|---|---|---|

|

A |

4.0 mm (0.157 in.) |

B |

5.0 mm (0.197 in.) |

|

C |

2.5 mm (0.0984 in.) |

D |

1.0 mm (0.0394 in.) |

(b) Remove the release paper and install the No. 2 front door stripe.

HINT:

Align the point (B) on the No. 2 front door stripe with the point (A) on the door frame and install the No. 2 front door stripe.

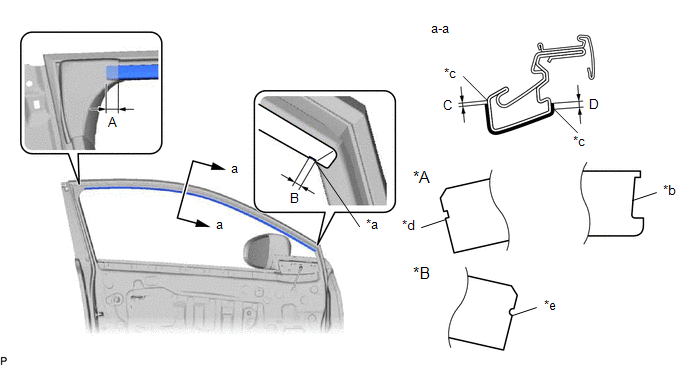

3. INSTALL FRONT DOOR OUTSIDE STRIPE

(a) Refer to the illustration to position a new front door outside stripe.

|

*A |

LH Side |

*B |

RH Side |

|

*a |

Point A |

*b |

Point B |

|

*c |

Edge of Curved Surface |

*d |

Square |

|

*e |

Round |

- |

- |

Standard Measurement:

|

Area |

Measurement |

Area |

Measurement |

|---|---|---|---|

|

A |

10.0 mm (0.394 in.) |

B |

4.0 mm (0.157 in.) |

|

C |

1.0 mm (0.0394 in.) |

D |

2.5 mm (0.0984 in.) |

(b) Remove the release paper and install the front door outside stripe.

HINT:

Align the point (B) on the front door outside stripe with the point (A) on the door frame and install the front door outside stripe.

4. INSTALL NO. 4 FRONT DOOR STRIPE

(a) Refer to the illustration to position a new No. 4 front door stripe.

|

*A |

LH Side |

*B |

RH Side |

|

*a |

Point A |

*b |

Point B |

|

*c |

Edge of Curved Surface |

*d |

Square |

|

*e |

Round |

- |

- |

Standard Measurement:

|

Area |

Measurement |

Area |

Measurement |

|---|---|---|---|

|

A |

3 mm (0.118 in.) |

B |

10.0 mm (0.394 in.) |

|

C |

1.0 mm (0.0394 in.) |

D |

-1.0 to 1.0 mm (-0.0394 to 0.0394 in.) |

(b) Remove the release paper and install the No. 4 front door stripe.

HINT:

Align the point (B) on the No. 4 front door stripe with the point (A) on the door frame and install the No. 4 front door stripe.

5. INSTALL FRONT DOOR FIX WINDOW GLASS

Click here

.gif)

.gif)

.gif)

6. INSTALL FRONT DOOR FRONT LOWER FRAME SUB-ASSEMBLY

Click here

.gif)

.gif)

.gif)

7. INSTALL FRONT DOOR GLASS RUN

Click here

.gif)

.gif)

.gif)

8. INSTALL DOOR FRAME UPPER GARNISH

Click here

.gif)

.gif)

.gif)

9. INSTALL FRONT DOOR GLASS SUB-ASSEMBLY

Click here

.gif)

.gif)

.gif)

10. INSTALL FRONT DOOR SERVICE HOLE COVER

Click here

.gif)

.gif)

.gif)

11. INSTALL OUTER REAR VIEW MIRROR ASSEMBLY

Click here

.gif)

.gif)

.gif)

12. INSTALL FRONT DOOR VENT SEAL

Click here

.gif)

.gif)

.gif)

13. INSTALL FRONT DOOR GLASS INNER WEATHERSTRIP

Click here

.gif)

.gif)

.gif)

14. INSTALL FRONT DOOR BELT SEAL

Click here

.gif)

.gif)

.gif)

15. CONNECT FRONT DOOR WEATHERSTRIP

Click here

.gif)

.gif)

.gif)

16. INSTALL FRONT DOOR LOWER FRAME BRACKET GARNISH

Click here

.gif)

.gif)

.gif)

17. INSTALL FRONT DOOR TRIM BOARD SUB-ASSEMBLY

Click here

.gif)

.gif)

.gif)

18. INSTALL MULTIPLEX NETWORK MASTER SWITCH ASSEMBLY WITH FRONT ARMREST BASE UPPER PANEL (for Driver Side)

Click here

.gif)

.gif)

.gif)

19. INSTALL POWER WINDOW REGULATOR SWITCH ASSEMBLY WITH FRONT ARMREST BASE UPPER PANEL (for Front Passenger Side)

Click here

.gif)

.gif)

.gif)

20. INSTALL FRONT DOOR INSIDE HANDLE BEZEL PLUG

Click here

.gif)

.gif)

.gif)

21. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Click here

.gif)

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

Click here

.gif)

.gif)

.gif)

22. INITIALIZE POWER WINDOW CONTROL SYSTEM

Click here

.gif)

23. INSPECT POWER WINDOW OPERATION

Click here

.gif)

.gif)

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration)

that must be performed after parts are removed and installed, or replaced during ...

Other materials:

Toyota CH-R Service Manual > Meter / Gauge System: Fuel Sender Open Detected (B1500)

DESCRIPTION

This DTC is stored when the combination meter assembly detects a fuel sender

gauge assembly malfunction via a direct line.

DTC No.

Detection Item

DTC Detection Condition

Trouble Area

Memory

B1500

Fuel ...

Toyota CH-R Service Manual > Audio And Visual System(for Radio And Display Type): Reverse Signal Circuit

DESCRIPTION

The radio and display receiver assembly receives a reverse signal from the park/neutral

position switch.

WIRING DIAGRAM

PROCEDURE

1.

CHECK BACK-UP LIGHT

(a) Move the shift lever to R and check if the back-up lights come on.

OK:

The back-up ligh ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0081