Toyota CH-R Service Manual: Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT LOWER NO. 1 SUSPENSION ARM SUB-ASSEMBLY

(a) Temporarily install the front lower No. 1 suspension arm sub-assembly LH to the front suspension crossmember sub-assembly with the 2 bolts and nut.

(b) Install the front lower No. 1 suspension arm sub-assembly LH to the front lower ball joint assembly LH with the bolt and 2 nuts.

Torque:

89 N·m {908 kgf·cm, 66 ft·lbf}

2. INSTALL FRONT WHEEL

Click here

.gif)

.gif)

3. STABILIZE SUSPENSION

Click here

.gif)

.gif)

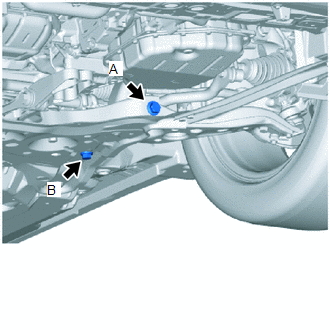

4. FULLY TIGHTEN FRONT LOWER NO. 1 SUSPENSION ARM SUB-ASSEMBLY

|

(a) Fully tighten the front lower No. 1 suspension arm sub-assembly with the 2 bolts. Torque: Bolt A : 240 N·m {2447 kgf·cm, 177 ft·lbf} Bolt B : 125 N·m {1275 kgf·cm, 92 ft·lbf} NOTICE: Because the nut has its own stopper, do not turn the nut. Tighten the bolt with the nut secured. |

|

5. INSTALL REAR ENGINE UNDER COVER LH

Click here

.gif)

.gif)

6. INSTALL NO. 1 ENGINE UNDER COVER

Click here

.gif)

.gif)

7. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

Click here

.gif)

.gif)

Components

Components

COMPONENTS

ILLUSTRATION

*1

NO. 1 ENGINE UNDER COVER

*2

REAR ENGINE UNDER COVER LH

N*m (kgf*cm, ft.*lbf): Specified torque

...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration)

that must be performed after parts are removed and installed, or replaced during ...

Other materials:

Toyota CH-R Service Manual > Blower Unit(for Valeo Made): Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL BLOWER RESISTOR (for Single Type)

(a) Engage the guides and install the blower resistor as shown in the illustration.

Install in this Direction

2. INSTALL AIR FILTER SUB-ASSEMBLY (for Single Type)

(a) Engage the guides t ...

Toyota CH-R Service Manual > Air Conditioning System(for Automatic Air Conditioning System With Top-mounted

Air Conditioner Pressure Sensor): Terminals Of Ecu

TERMINALS OF ECU

AIR CONDITIONING AMPLIFIER ASSEMBLY

HINT:

Check from the rear of the connector while it is connected to the air conditioning

amplifier assembly.

Terminal No. (symbol)

Wiring Color

Terminal Description

Condition

Specified ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.007