Toyota CH-R Service Manual: Blind Spot Monitor Sensor

Components

COMPONENTS

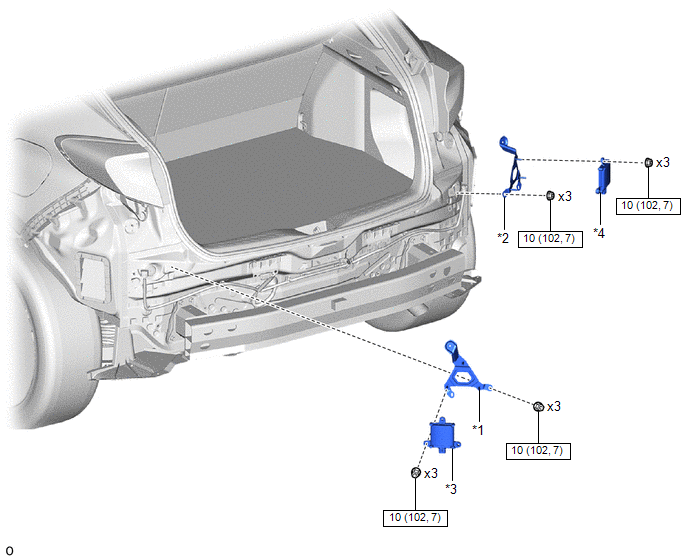

ILLUSTRATION

|

*1 |

BLIND SPOT MONITOR BRACKET LH |

*2 |

BLIND SPOT MONITOR BRACKET RH |

|

*3 |

BLIND SPOT MONITOR SENSOR LH |

*4 |

BLIND SPOT MONITOR SENSOR RH |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- |

- |

Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

- Avoid any impact to the blind spot monitor sensor.

- Do not drop the blind spot monitor sensor. If it is dropped, replace it with a new one.

HINT:

- The blind spot monitor beam axis inspection is performed to confirm whether the sensor is transmitting radio waves.

- The blind spot monitor beam axis confirmation is performed to confirm whether the sensor's beam axis is correct, and perform adjustment of the beam axis by using reflector.

- The blind spot monitor sensor installation condition inspection is performed to confirm whether the sensor is placed vertically to the ground (+/-5°) by using a jig, and that the sensor is 16 to 24° from the line parallel to the vehicle center line.

PROCEDURE

1. INSTALL BLIND SPOT MONITOR BRACKET LH

(a) Install the blind spot monitor sensor bracket LH with the 3 nuts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

2. INSTALL BLIND SPOT MONITOR BRACKET RH

HINT:

Use the same procedure as for the LH side.

3. INSTALL BLIND SPOT MONITOR SENSOR LH

(a) Connect the connector.

(b) Install the blind spot monitor LH with the 3 nuts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

4. INSTALL BLIND SPOT MONITOR SENSOR RH

HINT:

Use the same procedure as for the LH side.

5. PERFORM BLIND SPOT MONITOR SENSOR INSTALLATION CONDITION INSPECTION

Click here

.gif)

6. INSTALL REAR BUMPER ASSEMBLY

Click here

.gif)

7. PERFORM BLIND SPOT MONITOR BEAM AXIS CONFIRMATION

Click here

.gif)

SST: 09870-60000

09870-60010

SST: 09870-60040

8. PERFORM DIAGNOSTIC SYSTEM CHECK

Click here

.gif)

Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during the blind spot monitor sensor removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Replacement of blind spot monitor sensor |

Blind Spot Monitor Beam Axis Adjustment |

DTCs are output |

|

PROCEDURE

1. REMOVE REAR BUMPER ASSEMBLY

Click here

.gif)

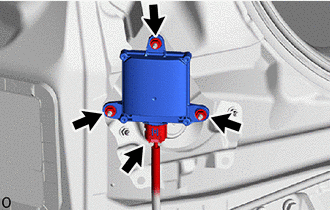

2. REMOVE BLIND SPOT MONITOR SENSOR LH

|

(a) Disconnect the connector. |

|

(b) Remove the 3 nuts and blind spot monitor sensor LH.

NOTICE:

Replace the blind spot monitor sensor LH if it has been dropped or subjected to a severe impact.

3. REMOVE BLIND SPOT MONITOR SENSOR RH

HINT:

Use the same procedure as for the LH side.

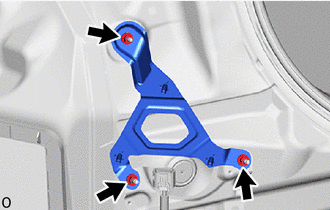

4. REMOVE BLIND SPOT MONITOR BRACKET LH

|

(a) Remove the 3 nuts and blind spot monitor bracket LH. |

|

5. REMOVE BLIND SPOT MONITOR BRACKET RH

HINT:

Use the same procedure as for the LH side.

Other materials:

Toyota CH-R Service Manual > Continuously Variable Transaxle System: Acceleration Sensor Malfunction (P1586)

DESCRIPTION

The ECM determines the vehicle inclination based on a signal from the airbag

sensor assembly (yaw rate and acceleration sensor). If a malfunction of the airbag

sensor assembly (yaw rate and acceleration sensor) is determined based on a malfunction

signal from the skid control ECU ...

Toyota CH-R Service Manual > Steering Wheel: Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

Do not replace the spiral cable with sensor sub-assembly with the battery

connected and the ignition switch ON.

Do not rotate the spiral cable with sensor sub-assembly without the

steering wheel assembly installed with the battery c ...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.009