Toyota CH-R Service Manual: No Signal from Transmitter ID1 (C2121/21-C2125/25,C2181/81-C2185/85)

DESCRIPTION

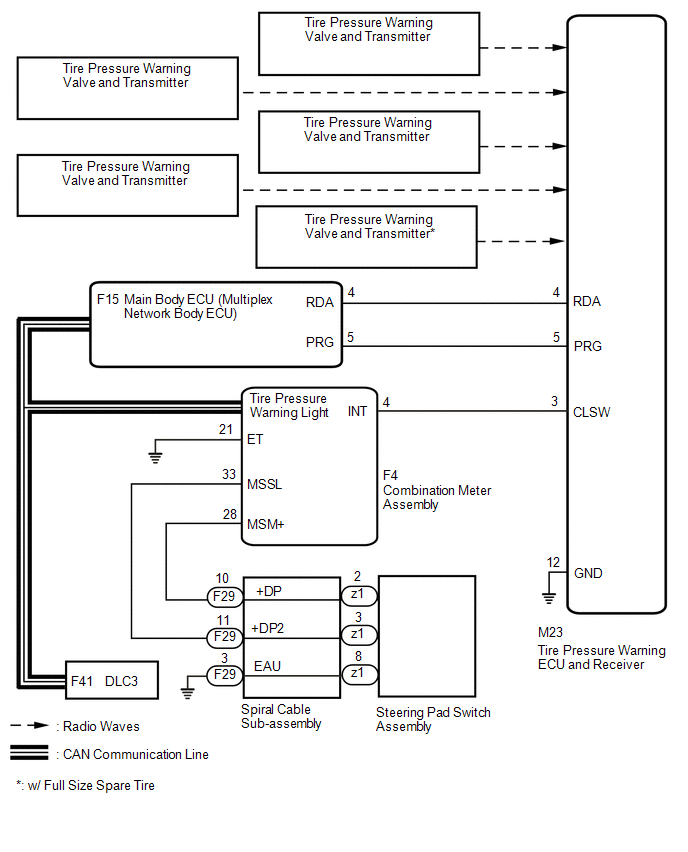

The tire pressure warning valve and transmitters that are installed in the tire and wheel assemblies measure the tire pressures. The measured values are transmitted to the tire pressure warning ECU and receiver in the vehicle as radio waves. The ECU compares the measured tire pressure values with the tire pressure threshold. When the measured tire pressure value is less than this threshold, the warning light in the combination meter assembly illuminates.

The tire pressure warning valve and transmitters constantly send radio waves to the tire pressure warning ECU and receiver.

Under the conditions below, the tire pressure warning ECU and receiver is unable to receive the signals from the tire pressure warning valve and transmitters, and a DTC is stored.

- Facilities or devices that use similar radio frequencies are located in the vicinity of the vehicle.

- Devices using similar radio frequencies are used in the vehicle.

- The ID of a tire pressure warning valve and transmitter is mistyped during registration.

- A tire, wheel and/or transmitter from a different vehicle is installed.

HINT:

When no transmitter ID is received from a tire pressure warning valve and transmitter for 20 minutes or more while the vehicle speed is more than 40 km/h (25 mph), or no transmitter ID is received from any of the tire pressure warning valve and transmitters for 20 minutes or more, DTCs from C2121/21 to C2124/24 (C2125/25: w/ Full Size Spare Tire) are stored.

DTCs C2121/21 to C2124/24 (C2125/25: w/ Full Size Spare Tire) can only be cleared by using the Techstream. DTCs C2181/81 to C2184/84 (C2185/85: w/ Full Size Spare Tire) can be cleared when the tire pressure warning valve and transmitter sends a forced transmission signal or test mode ends. DTCs C2181/81 to C2184/84 (C2185/85: w/ Full Size Spare Tire) are output only in test mode.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

Note |

|---|---|---|---|---|

|

C2121/21 |

No Signal from Transmitter ID1 |

Either of the following conditions (a) or (b) is met: (a) When all conditions below are met:

(b) When both conditions below are met:

|

|

- |

|

C2122/22 |

No Signal from Transmitter ID2 |

Either of the following conditions (a) or (b) is met: (a) When all conditions below are met:

(b) When both conditions below are met:

|

|

- |

|

C2123/23 |

No Signal from Transmitter ID3 |

Either of the following conditions (a) or (b) is met: (a) When all conditions below are met:

(b) When both conditions below are met:

|

|

- |

|

C2124/24 |

No Signal from Transmitter ID4 |

Either of the following conditions (a) or (b) is met: (a) When all conditions below are met:

(b) When both conditions below are met:

|

|

- |

|

C2125/25 |

No Signal from Transmitter ID5 |

Either of the following conditions (a) or (b) is met: (a) When all conditions below are met:

(b) When both conditions below are met:

|

|

w/ Full Size Spare Tire |

|

C2181/81 |

Transmitter ID1 not Received (Test Mode DTC) |

Test mode procedure is performed. |

|

- |

|

C2182/82 |

Transmitter ID2 not Received (Test Mode DTC) |

Test mode procedure is performed. |

|

- |

|

C2183/83 |

Transmitter ID3 not Received (Test Mode DTC) |

Test mode procedure is performed. |

|

- |

|

C2184/84 |

Transmitter ID4 not Received (Test Mode DTC) |

Test mode procedure is performed. |

|

- |

|

C2185/85 |

Transmitter ID5 not Received (Test Mode DTC) |

Test mode procedure is performed. |

|

w/ Full Size Spare Tire |

NOTICE:

When DTCs C2121/21 to C2124/24 (C2125/25: w/ Full Size Spare Tire) are stored, DTC C2179/79 may be stored simultaneously. In such cases, troubleshoot DTCs C2121/21 to C2124/24 (C2125/25: w/ Full Size Spare Tire) first, then troubleshoot DTC C2179/79.

HINT:

It is necessary to perform the following procedure to identify the tire pressure warning valve and transmitter that is malfunctioning because it cannot be identified by the output DTC.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When replacing the tire pressure warning ECU and receiver, read the

transmitter IDs stored in the old ECU using the Techstream and write them

down before removal.

Click here

.gif)

- It is necessary to perform initialization

.gif) after registration

after registration

.gif) of the transmitter IDs into the tire pressure warning ECU and receiver if

the ECU and/or one of the valve and transmitters has been replaced.

of the transmitter IDs into the tire pressure warning ECU and receiver if

the ECU and/or one of the valve and transmitters has been replaced.

PROCEDURE

|

1. |

CHECK FREQUENCY RECEIVING CONDITION |

(a) Check that the following conditions are not met:

(1) Facilities or devices that use similar radio frequencies are located in the vicinity of the vehicle.

HINT:

If the vehicle is located in an area such as the one described above, the tire pressure warning light may come on only in a particular area.

(2) Devices using similar radio frequencies are used in the vehicle.

OK:

Facilities or devices that use similar radio frequencies are not located in the vicinity of the vehicle.

HINT:

Radio transmissions may be interrupted due to the surroundings or devices installed by the user.

| NG | .gif) |

CHECK IF ANY DEVICE IS INSTALLED BY USER |

|

|

2. |

IDENTIFY TRANSMITTER CORRESPONDING TO DTC |

(a) Set the tire pressure to the specified value.

Click here

.gif)

.gif)

.gif)

(b) Turn the ignition switch off.

(c) Connect the Techstream to the DLC3.

(d) Turn the ignition switch to ON.

(e) Turn the Techstream on.

(f) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(g) Display the "ID Tire Inflation Pressure" value for each wheel using the Techstream.

(h) Rapidly reduce the tire pressure for each wheel at least 40 kPa (0.4 kgf/cm2, 5.8 psi) within 30 seconds. If the "ID Tire Inflation Pressure" value displayed on the Techstream does not change, the tire pressure warning valve and transmitter corresponding to the unchanged "ID Tire Inflation Pressure" value was the cause of the output DTC.

HINT:

- Identify the malfunctioning tire pressure warning valve and transmitter by repeatedly decreasing the tire pressure for each tire.

- Record which "ID Tire Inflation Pressure" value corresponds to each tire.

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

ID 1 Tire Inflation Pressure |

ID1 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 2 Tire Inflation Pressure |

ID2 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 3 Tire Inflation Pressure |

ID3 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge)/ 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 4 Tire Inflation Pressure |

ID4 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 5 Tire Inflation Pressure |

ID5 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

|

HINT:

- *1: It may take a few minutes until the values are displayed.

- *2: w/ Full Size Spare Tire

|

Tester Display |

|---|

|

ID 1 Tire Inflation Pressure |

|

ID 2 Tire Inflation Pressure |

|

ID 3 Tire Inflation Pressure |

|

ID 4 Tire Inflation Pressure |

|

ID 5 Tire Inflation Pressure |

(i) Check the Data List.

NOTICE:

- It may take a few minutes to display the updated tire pressure data.

- When an "ID Tire Inflation Pressure" value has not changed, reset the tire pressure to the appropriate specified value and rotate the tire 90 to 270 degrees. Then rapidly release the tire pressure and recheck the value.

- Record the transmitter ID of which "ID Tire Inflation Pressure" values corresponds to each tire.

(j) After confirming that the "ID Tire Inflation Pressure" value for one tire has changed, repeat this procedure for each tire. Identify the transmitter that corresponds to the DTC.

|

Result |

Proceed to |

|---|---|

|

One or more transmitter is abnormal |

A |

|

All transmitters are normal |

B |

| B | .gif) |

END |

|

|

3. |

CHECK TRANSMITTER ID |

(a) Turn the ignition switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(f) Check the values by referring to the table below.

Chassis > Tire Pressure Monitor > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Registered ID 1 Code |

Registered ID1 code |

min.: 0 max.: FFFFFFF*1 |

ID No. registered for transmitter ID1 displayed |

- |

|

Registered ID 2 Code |

Registered ID2 code |

min.: 0 max.: FFFFFFF*1 |

ID No. registered for transmitter ID2 displayed |

- |

|

Registered ID 3 Code |

Registered ID3 code |

min.: 0 max.: FFFFFFF*1 |

ID No. registered for transmitter ID3 displayed |

- |

|

Registered ID 4 Code |

Registered ID4 code |

min.: 0 max.: FFFFFFF*1 |

ID No. registered for transmitter ID4 displayed |

- |

|

Registered ID 5 Code |

Registered ID5 code |

min.: 0 max.: FFFFFFF*1 |

ID No. registered for transmitter ID5 displayed |

*2 |

HINT:

- *1: Displayed only when the ID No. is not registered.

- *2: w/ Full Size Spare Tire

- The wheel position cannot be determined from ID1 through ID4 (ID5: w/ Full Size Spare Tire) on the Data List.

|

Tester Display |

|---|

|

Registered ID 1 Code |

|

Registered ID 2 Code |

|

Registered ID 3 Code |

|

Registered ID 4 Code |

|

Registered ID 5 Code |

(g) Check the ID number on the identified transmitter by removing it from the tire and wheel.

.png)

|

*1 |

Tire Pressure Warning Valve and Transmitter |

- |

- |

|

*a |

Transmitter ID (7-digit Number) |

- |

- |

(h) Confirm that the ID number on the transmitter and recorded transmitter ID match.

|

Result |

Proceed to |

|---|---|

|

Match |

A |

|

Do not match |

B |

| B | .gif) |

GO TO STEP 5 |

|

|

4. |

REPLACE TIRE PRESSURE WARNING VALVE AND TRANSMITTER |

(a) Replace the tire pressure warning valve and transmitter.

Click here

.gif)

|

|

5. |

REGISTRATION OF TRANSMITTER ID |

(a) Perform registration.

Click here

.gif)

|

|

6. |

PERFORM INITIALIZATION |

(a) Set the tire pressure to the specified value.

Click here

.gif)

.gif)

.gif)

(b) Perform initialization.

Click here

.gif)

|

|

7. |

CONFIRM TIRE INFLATION PRESSURE (DATA LIST) |

(a) Turn the ignition switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(f) Check the values by referring to the table below.

Chassis > Tire Pressure Monitor > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

ID 1 Tire Inflation Pressure |

ID1 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 2 Tire Inflation Pressure |

ID2 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 3 Tire Inflation Pressure |

ID3 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 4 Tire Inflation Pressure |

ID4 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 5 Tire Inflation Pressure |

ID5 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

|

HINT:

- *1: It may take a few minutes until the values are displayed.

- The wheel position cannot be determined from ID1 through ID4 (ID5: w/ Full Size Spare Tire) on the Data List.

- When an "ID Tire Inflation Pressure" value has not changed, reset the tire pressure to the appropriate specified value and rotate the tire 90 to 270 degrees. Then rapidly release the tire pressure and recheck the value.

- *2: w/ Full Size Spare Tire

|

Tester Display |

|---|

|

ID 1 Tire Inflation Pressure |

|

ID 2 Tire Inflation Pressure |

|

ID 3 Tire Inflation Pressure |

|

ID 4 Tire Inflation Pressure |

|

ID 5 Tire Inflation Pressure |

|

Result |

Proceed to |

|---|---|

|

Tire pressure values are not displayed. |

A |

|

All tire pressure readings are equal to specified values. |

B |

| A | .gif) |

REPLACE TIRE PRESSURE WARNING ECU AND RECEIVER |

| B | .gif) |

END |

Diagnostic Trouble Code Chart

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

Tire Pressure Warning ECU and Receiver

DTC No.

Detection Item

Note

Link

B1247

Tire Pressure Moni ...

Transmitter ID not Received in Main Mode (C2126/26)

Transmitter ID not Received in Main Mode (C2126/26)

DESCRIPTION

After all IDs are registered, DTC C2126/26 is stored in the tire pressure warning

ECU and receiver and the tire pressure warning light blinks for 1 minute and then

illuminates.

When ...

Other materials:

Toyota CH-R Owners Manual > Tire information: Uniform Tire Quality Grading

This information has been prepared in accordance with regulations issued by the

National Highway Traffic Safety Administration of the U.S. Department of Transportation.

It provides the purchasers and/or prospective purchasers of Toyota vehicles with

information on uniform tire quality grading.

...

Toyota CH-R Service Manual > Compressor(for Valeo Made): Installation

INSTALLATION

PROCEDURE

1. ADJUST COMPRESSOR OIL

(a) When replacing the compressor with pulley assembly with a new one,

gradually discharge the refrigerant gas from the service valve. Then drain

the following amount of oil from the new compressor with pulley assembly

before ...

Toyota C-HR (AX20) 2023-2025 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.0105

.gif)