Toyota CH-R Service Manual: Adjustment

ADJUSTMENT

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after completing the rear wheel alignment procedure are shown below.

Necessary Procedures After Procedure Performed|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Rear wheel alignment adjustment |

|

|

|

PROCEDURE

1. INSPECT TIRES

Click here

.gif)

.gif)

2. MEASURE VEHICLE HEIGHT

Click here

.gif)

3. INSPECT CAMBER

NOTICE:

Inspect while the vehicle is unloaded.

|

(a) Install a camber-caster-kingpin gauge. |

|

(b) Inspect the camber.

Camber (Unloaded Vehicle):

|

Vehicle Model |

Camber Inclination |

Right-left Difference |

|---|---|---|

|

ZGX10L-AHXEPX ZGX10L-AHXGPX ZGX10L-AHXNPX |

-0°43' +/- 0°45' (-0.72° +/- 0.75°) |

0°45' (0.75°) or less |

|

ZGX10L-BHXNPA |

-0°51' +/- 0°45' (-0.85° +/- 0.75°) |

0°45' (0.75°) or less |

HINT:

Camber is not adjustable. If the measurement is not within the specified range, inspect the suspension parts for damage and/or wear, and replace them if necessary.

4. INSPECT TOE-IN

NOTICE:

Inspect while the vehicle is unloaded.

(a) Bounce the vehicle up and down at the corners to stabilize the suspension.

(b) Release the parking brake and move the shift lever to N.

(c) Push the vehicle straight ahead approximately 5 m (16.4 ft.). (Step A)

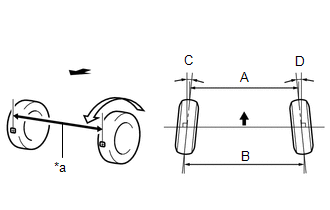

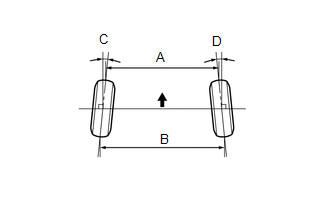

(d) Put tread center marks on the rearmost points of the rear wheels and measure the distance between the marks (dimension B).

|

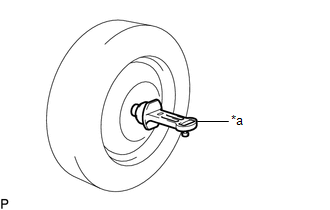

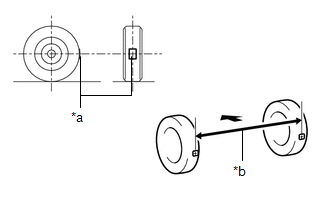

*a |

Tread Center Mark |

|

*b |

Dimension B |

.png) |

Front of the Vehicle |

(e) Slowly push the vehicle straight ahead to cause the rear wheels to rotate 180°. Use the rear tire valve as a reference point.

HINT:

Do not allow the wheels to rotate more than 180°. If the wheels rotate more than 180°, perform the procedure from step A again.

(f) Measure the distance between the tread center marks on the front of the rear wheels (dimension A).

|

*a |

Dimension A |

.png) |

Front of the Vehicle |

Toe-in (Unloaded Vehicle):

|

Vehicle Model |

Specified Condition |

|---|---|

|

ZGX10L-AHXEPX ZGX10L-AHXGPX ZGX10L-AHXNPX |

C + D: 0°10' +/- 0°10' (0.17° +/- 0.17°) |

|

B - A: 2.0 +/- 2.0 mm (0.0787 +/- 0.0787 in.) |

|

|

ZGX10L-BHXNPA |

C + D: 0°17' +/- 0°10' (0.28° +/- 0.17°) |

|

B - A: 3.0 +/- 2.0 mm (0.118 +/- 0.0787 in.) |

HINT:

Measure "B - A" only when "C + D" cannot be measured.

If the toe-in is not within the specified range, adjust it at the rear suspension toe adjust cam sub-assembly.

5. ADJUST TOE-IN

|

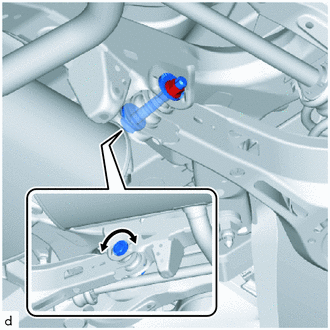

(a) Loosen the nut of the rear No. 2 suspension arm assembly (on the rear suspension member sub-assembly side). NOTICE: Hold the rear suspension toe adjust cam sub-assembly while rotating the nut. |

|

(b) Rotate the rear suspension toe adjust cam sub-assembly to adjust the toe-in.

Toe-in (Unloaded Vehicle):

|

Vehicle Model |

Specified Condition |

|---|---|

|

ZGX10L-AHXEPX ZGX10L-AHXGPX ZGX10L-AHXNPX |

C + D: 0°10' +/- 0°05' (0.17° +/- 0.08°) |

|

B - A: 2.0 +/- 1.0 mm (0.0787 +/- 0.0394 in.) |

|

|

ZGX10L-BHXNPA |

C + D: 0°17' +/- 0°05' (0.28° +/- 0.08°) |

|

B - A: 3.0 +/- 1.0 mm (0.118 +/- 0.0394 in.) |

HINT:

- Rotating the rear suspension toe adjust cam sub-assembly by one notch changes the toe by approximately 2.9 mm (0.114 in.).

- Perform adjustments so that the value is as close as possible to the median of the specified range.

.png) |

Front of the Vehicle |

(c) Tighten the nut of the rear No. 2 suspension arm assembly (on the rear suspension member sub-assembly side).

Torque:

100 N·m {1020 kgf·cm, 74 ft·lbf}

NOTICE:

Hold the rear suspension toe adjust cam sub-assembly while rotating the nut.

6. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

7. PERFORM YAW RATE AND ACCELERATION SENSOR CALIBRATION

Click here

.gif)

Front Suspension

Front Suspension

...

Other materials:

Toyota CH-R Service Manual > Shift Lever: Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE SHIFTING HOLE COVER SUB-ASSEMBLY

(a) Disengage the 4 guides and 6 claws to remove the shifting hole cover

sub-assembly from the upper console panel sub-assembly.

2. REMOVE SHIFT POSITION INDICATOR

...

Toyota CH-R Service Manual > Rear Door Window Frame Moulding: Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

PROCEDURE

1. INSTALL REAR DOOR REAR WINDOW FRAME MOULDING

(a) Using an air riveter or hand riveter with a nose piece, install the rear

...

Toyota C-HR (AX20) 2023-2026 Owner's Manual

Toyota CH-R Owners Manual

- For safety and security

- Instrument cluster

- Operation of each component

- Driving

- Interior features

- Maintenance and care

- When trouble arises

- Vehicle specifications

- For owners

Toyota CH-R Service Manual

- Introduction

- Maintenance

- Audio / Video

- Cellular Communication

- Navigation / Multi Info Display

- Park Assist / Monitoring

- Brake (front)

- Brake (rear)

- Brake Control / Dynamic Control Systems

- Brake System (other)

- Parking Brake

- Axle And Differential

- Drive Shaft / Propeller Shaft

- K114 Cvt

- 3zr-fae Battery / Charging

- Networking

- Power Distribution

- Power Assist Systems

- Steering Column

- Steering Gear / Linkage

- Alignment / Handling Diagnosis

- Front Suspension

- Rear Suspension

- Tire / Wheel

- Tire Pressure Monitoring

- Door / Hatch

- Exterior Panels / Trim

- Horn

- Lighting (ext)

- Mirror (ext)

- Window / Glass

- Wiper / Washer

- Door Lock

- Heating / Air Conditioning

- Interior Panels / Trim

- Lighting (int)

- Meter / Gauge / Display

- Mirror (int)

- Power Outlets (int)

- Pre-collision

- Seat

- Seat Belt

- Supplemental Restraint Systems

- Theft Deterrent / Keyless Entry

0.009